Business Leaders Discuss the Challenges Facing Recycling

At a virtual event, business leaders discussed the recycled plastic demand gap and other challenges.

Last week, Chemical Market Analytics, part of the Oil Price Information Service (OPIS), presented an event titled “Plastics Recycling and the Circular Economy,” joined by leaders from Blackrock, Cyclyx, Tricon Energy, and Encina.

Scaling up circularity in plastics will require social innovation as well as technological.

Photo Credit: Getty Images

The first session focused on the problems and challenges facing recycling. Anthony Palmer, v.p. at Chemical Market Analytics, led a discussion with Michael Lacey, sustainable product manager at Tricon Energy and Sheida Sahandy, chief sustainability officer at Encina.

Palmer framed the status of plastics recycling in terms of “five truths”: an anticipated rise in plastic waste generation, the slow growth rate of recycling relative to that rise, the demand for recyclate that is outpacing supply, the need for new technologies that can reduce carbon emissions under conditions of increased production, and reliance on fossil-based feedstocks will continue to increase for now.

Minding The Gap

Only a small percentage of the plastic used globally is currently being recycled after use (9% in the U.S. as of 2018), a situation that is expected to get even more challenging as plastic consumption increases. A large portion of that increased production is expected to occur in regions where waste management is already a significant problem due to infrastructure constraints, creating a logistical element.

Lacey pointed out the increased attention and awareness about plastic waste in recent years, and predicted that it will lead to better education, better understanding, and more investment that will in turn boost recycling rates. Sahandy highlighted the opportunity of chemical recycling to complement mechanical recycling and make use of a broader range of feedstocks.

Extended producer responsibility (EPR) strategies attempt to build environmental costs into the price of making a product, thereby encouraging manufacturers to keep environmental impacts to a minimum. These strategies have been part of many recent plastic regulations, including that passed by California in June.

Sahandy commented on the benefits of putting responsibility in the hands of those who are in the position to make the needed changes and work together in new ways. In a linear economy, partnerships exist between immediately adjacent participants in the value chain, but in a circular economy, partnerships are needed throughout the value chain. This creates opportunities for unlikely partners to work together to find new solutions.

Lacey stressed the need to harmonize EPR strategies. Currently, fragmentation exists among individual states in the US and among individual countries in Europe. A national/continental system based on the EPR ideas that have proven most effective could simplify the system and make it more effective.

Circular Plastics in a Net Zero Carbon Future

The second session focused on moving beyond today’s problems with recycling and some of the social forces needed to create an economy that avoids waste and achieves carbon goals. This time, Palmer was joined by Bill Cooper, v.p. at Cyclyx, and Tomas Peshkatari, managing director at Blackrock.

Peshkatari discussed the role private capital plays in the circular transition. Investment will be needed to build the capability to meet the scale of demand for recycled content, and investors will need to take a long term view to see the results. ESG (environmental, social, and corporate governance) has become a global movement in investing, with more consumers considering the impacts of their investing decisions along with all of their other purchases. According to Peshkatari, 87% of investors say ESG will become more important over a five-year period, and circular plastics are at the heart of what ESG is all about.

Partnerships to aggregate waste streams are another important social activity to the creation of a circular economy for plastics. Waste management systems function differently in different localities, so understanding local processes and the characteristics of the waste, sorted or unsorted, is important. Cooper pointed to his company’s collaboration with Exxon, Lyondell, FCC Environmental, and the City of Houston as a model for collaborating to turn waste into pyrolysis feedstock, by better characterizing and aggregating difficult-to-recycle waste.

The event was part of the Dow Jones Energy & Sustainability Issue Briefing Event Series. The Dow Jones Company acquired OSIS in 2021.

Related Content

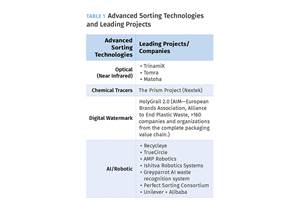

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More