April 24, 2025

A letter from our CEO

Dear Stakeholder,

2024 was a transformative year for Agilyx. In June, we made a significant strategic shift from being primarily a developer of proprietary catalyst-free depolymerization technology to an investment holding company. Our focus is to maximize the potential of waste plastic feedstock management and custom formulations through Cyclyx, and of advanced polystyrene recycling technology with Styrenyx. This new direction aligns with our commitment to enable plastic circularity on a global and commercial scale while accelerating the shift to a low-carbon economy. For more than 20 years, Agilyx has been at the forefront of advanced recycling, pioneering technologies that have reshaped the industry. With 22 patents and a series of industry firsts, we have developed an unparalleled understanding of post-use plastic chemistry, contamination impacts, and the complexities of diverse waste streams.

Cyclyx customized feedstock: The cornerstone of recycling

Recognizing feedstock availability’s critical role in the recycling effort, our renewed focus centers on Cyclyx, our joint venture with ExxonMobil (25%) and LyondellBasell (25%) dedicated to increasing the recyclability of plastic waste by custom formulating it into valuable feedstock for new products. Through our extensive experience in waste characterization and handling contamination, we have developed an unmatched ability to optimize feedstock streams for diverse advanced and mechanical recycling technologies. This expertise positions us to address the critical industry bottleneck: the consistent supply of high-quality recycled plastic feedstock. Cyclyx is an essential bridge between waste producers and recyclers, ensuring that plastic waste is collected and inputs tailored to industrial needs.

Styrenyx advanced recycling: Recovering the value of plastic

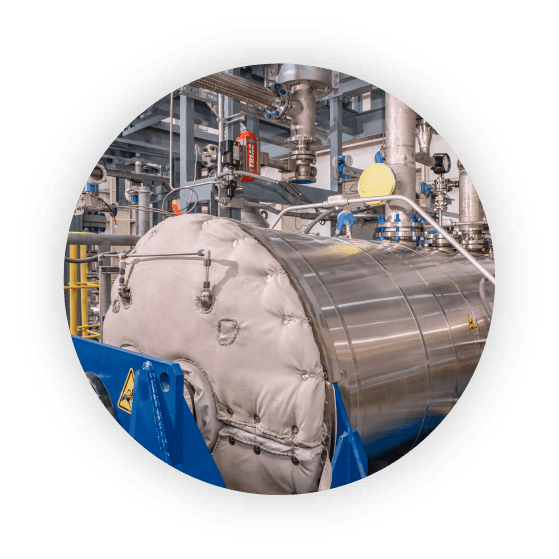

Styrenyx, our proprietary depolymerization process enables polystyrene to be recycled repeatedly, reducing reliance on virgin resources and significantly lowering carbon footprints.

The year in brief

This year, Cyclyx continued to progress development of the Cyclyx Circularity Centers. The final investment decision for the second center, to be located in the Dallas-Fort Worth area, was taken in late 2024, marking a major milestone in the expansion of recycling infrastructure. Like the first center in Houston, this center is designed to process plastic waste into custom feedstock for recycling. Together with ExxonMobil and LyondellBasell, Agilyx invested $135 million in its development, with Agilyx’s $67.5 million pro-rata stake fully financed through equity and green bond transactions. Together, both Circularity Centers will have the capacity to produce an estimated 300,000 metric tons of feedstock annually, further strengthening our role in the circular plastics economy. We are also excited to have achieved the start of operations at Toyo Styrene’s (a member of the Denka group) facility in Japan. This facility showcases the latest generation of Styrenyx technology, highlighting our progress in scaling solutions for the circular economy. Learnings and successes over the years have played a critical role in demonstrating that advanced recycling of polystyrene is both feasible, as evidenced by facilities like Toyo, and essential to this global shift. Financially, we have reinforced our position through strategic capital raises, including a $40 million equity private placement in August and a $50 million senior secured green bond in November. Together, the raises provide the necessary resources to support the development of Cyclyx’s second Circularity Center and other corporate initiatives. Finally, we are very pleased to have launched our latest initiative, Plastyx—a 60/40 joint venture between Agilyx ASA and Circular Resources SARL. Plastyx is establishing sourcing supply chains in Europe to supply advanced recycling feedstocks to a wide range of customers, including working in close partnership with Cyclyx to support its inbound plastic demand.

Looking ahead

Our goal is clear: bridge the gap between waste producers and advanced recyclers, ensuring a steady supply of high-quality, process-ready feedstock. By supplying feedstock derived from post-use plastic and developing and marketing innovative, advanced recycling technology, we are driving meaningful change in the industry. With a strong and growing opportunity to deliver additional post-use plastic processing centers, Agilyx is poised to redefine the future of plastic recycling. As we embark on this new chapter, I want to thank our shareholders, partners, and employees for their continued support. Together, we are using technology for good, building a circular economy for plastics by turning waste into value.

Ranjeet Bhatia

Chief Executive Officer of Agilyx

What the advanced recycling industry needs to support its growth and sustainability contributions

While advanced plastic recycling technologies are scaling industrially and complementing mechanical recycling, the industry’s growth remains constrained by the availability of consistent, high-quality feedstock. Plastyx is designed to bridge this gap by developing partnerships and material processing capabilities to ensure a reliable supply of high-quality polymers for food-grade and other high-performance packaging applications.

Plastyx at a glance

What Plastyx does

Act as a feedstock aggregator and pretreatment processor of plastic waste

Operate in a merchant capacity to supply material specified for the range of advanced recycling requirements

Technology agnostic, focused on rigorous quality standards, reliability and long-term value

Agilyx is committed to building an international sourcing platform to support waste plastic feedstock supply. Carlos is a leader in our field and has an unparalleled understanding of the advanced recycling industry. By combining market-leading feedstock management capabilities with Carlos’ expertise, we are creating a first mover in this critical market segment.

Ranjeet Bhatia, CEO of Agilyx

Learn more about Plastyx

ExploreProducts & Services

Plastic waste solutions

From feedstock management to advanced recycling technology, Agilyx helps solve the problem of plastic waste by investing in solutions that help shift our world from a linear, “make-take-waste” economy, to a more sustainable “retrieve-restore-recycle” economy, aiding the transition to a lower-carbon future.

Our Solutions

Cyclyx

A pioneer and key enabler for the recycling industry, converting post-use plastic waste into high-quality feedstock

Styrenyx

Agilyx’s proprietary advanced recycling technology for polystyrene waste, available for licensing and equipment sourcing

TruStyrenyx

Polystyrene waste to styrene monomer platform combining Styrenyx depolymerization and Technip Energies’ purification technologies

Our Services

Agilyx’s technical services leverage decades of expertise in chemical technology to deliver innovative, scalable solutions for plastic waste. From process design to operator training, our team provides the technical knowledge and support needed to optimize recycling systems and drive circularity.

Agilyx Research Center Services

The Agilyx Research Center (the ARC) provides a range of services to characterize and identify plastic streams that could be turned into feedstock sources and match those to advanced recycling processes. Projects can range from small-scale lab, through pilot plant to full-scale identification and design of commercial facilities.

Rapid matching using our extensive

feed-to-product expertise

Bench & pilot-scale advanced depolymerization

Feed, product and by-product physical and chemical analysis

Feed characterization services

Generation of multi-liter quantities of products for evaluation purposes

Packaged Feasibility Studies

Detailed feedstock specification definition

Providing Experimental Data Inputs for scale-up & commercial designs

Pre- and post-process treatment

Technical Collaborations

Includes R&D design and technical services – from a process design package (PDP) to detailed design, integration, permitting support, and other project support needs

Equipment Supply

Agilyx will source, sell and supply all necessary equipment for our depolymerization process, including our proprietary pyrolysis reactor and oil conditioning system

Commissioning Services

Services to commission the supplied core equipment, provide integration support,

and basic operational training

Operator Training Program

We offer a comprehensive “train-the-trainer” program to ensure customers produce the maximum value from the process

With decades of expertise in plastics and advanced recycling, Agilyx has developed a deep understanding of the chemical complexity of plastic waste. Our knowledge drives innovation, enabling scalable solutions that transform plastic waste into valuable resources.

Dr. Chris Faulkner, Chief Techology Officer

To solve the plastic recycling problem, collaboration is key Across the value chain, Agilyx excels as a collaborator in solving the plastic waste problem. We understand that recycling is never a one-size-fits-all solution. Our flexible approach allows us to tailor solutions for our customers’ specific needs.

Make an inquiry

Across the value chain, Agilyx excels as a collaborator in solving the plastic waste problem. We understand that recycling is never a one-size-fits-all solution. Our flexible approach allows us to tailor solutions for our customers’ specific needs.

Agilyx is changing the way the world recycles

Agilyx is dedicated to solving the problem of plastic waste by investing in solutions across the value chain, from feedstock supply derived from post-use plastics to the recycling industry, to innovative advanced recycling technology.

Contact us

Increasing the recyclability of post-use plastics

Offering solutions for plastic waste through advanced recycling technology and feedstock processing capabilities

Solving the plastic waste crisis will require paradigm-breaking systems and technology. At Agilyx, we are investing in solutions that turn plastic waste into a valuable resource that can be used in the production of virgin-equivalent recycled material for reuse.

Ranjeet Bhatia, CEO

Our Solutions

Cyclyx

Cyclyx is a joint venture among Agilyx (50%), ExxonMobil (25%), and LyondellBasell (25%) to convert post-use plastic waste into high-quality feedstock for both mechanical and advanced recycling applications.

Styrenyx

We license our depolymerization technology for polystyrene waste recycling. We source, sell and supply all the necessary core equipment to make the project successful.

Agilyx Research Center

Through a collaborative approach, we offer design and engineering services, engineering integration, permitting support and other project support services that are tailored to our customers’ recycling needs.

Plastyx

Plastyx is a European-sourced feedstock supplier to the European advanced recycling industry. Through partnerships and material processing capabilities, the availability of high-quality polymers for food contact and other technical packaging applications is being rapidly scaled.

Investing in

solutions for plastic waste

Agilyx offers a compelling investment opportunity within the recycling industry, with well-funded projects driving growth and a clear pathway to profitability.

Moving towards a

lower-carbon future

Working with our customers, we are creating and supporting circular models where plastics can be used, recycled, and reused again and again. Closing the loop by replacing virgin plastic production with recycled material keeps plastics out of landfills and our environment, reduces demand for fossil resources, like oil and gas, and lowers greenhouse gas emissions.