OSLO, Norway – February 29, 2024 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, announced today that it has reached an agreement with Americas Styrenics (AmSty), its joint venture partner, to close Regenyx after successfully achieving the objectives defined in its five year formation agreement.

Regenyx, located in Tigard, Oregon (US), is a 50/50 joint venture between AmSty and Agilyx. The company converts post-use polystyrene back into its original components for production under AmSty’s PolyRenew® label. Regenyx showcases Agilyx depolymerization technology and enables AmSty to produce new polystyrene that is used to make products with the same quality and durability as virgin plastic. Over the course of the five-year project, Regenyx diverted over 6 million pounds of post-use polystyrene waste from landfills.

“Because of Regenyx, the new circular plastics economy now has a place for polystyrene, and this essential material that improves people’s lives has even more potential for growth,” said Tim Barnette, AmSty vice president of polymers and sustainability. “AmSty is proud to have been part of this long-term project that proves advanced recycling of polystyrene is not only feasible, it is the future.”

“We are very proud of our team and our company for the important work we’ve done over the past five years in Tigard,” said Russ Main, interim CEO of Agilyx. “Building this first-of-its-kind circular recycling model for polystyrene in the US opened the door for Agilyx to progress additional commercial projects, such as the Toyo Styrene plant in Japan which is nearing completion of commissioning and will showcase the latest generation of Agilyx technology.”

The Regenyx venture achieved many milestones including establishment of ISCC PLUS certification for the demonstrated circular pathway. The venture also allowed both parent companies to develop and progress additional projects and pathways at larger scale. Having successfully delivered its defined project objectives, Agilyx and AmSty will decommission the Regenyx venture at the end of the five-year agreement. The plant will cease operations by April 30, 2024, alongside the wind down of the venture.

For media inquiries:

Melanie Burger

Director, Corporate Communications

communications@agilyx.com

For investor inquiries:

Louise Bryant

SVP, Investor Relations & Sustainability

+44 7813 210 809

investors@agilyx.com

ABOUT AGILYX

Agilyx ASA is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a chemical recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale waste polystyrene chemical recycling facility via pyrolysis enabling closed loop polystyrene plastic-to-plastic and holds 20 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com or follow us on Linkedin.

INVESTOR REPORTS & PRESENTATIONS

The latest releases, reports and webcasts

Explore our latest presentation

2025

2025 H1 Results and Investor Presentation |

Report | Presentation | Webcast |

2025 Listing Prospectus |

Statement | ||

Styrenyx Product Carbon Footprint Report |

Report | ||

GreenDot Acquisition Management Presentation |

Presentation | ||

April Update Meeting |

Presentation | Webcast | |

2024

2024 Annual Report |

Report | ||

2024 H2 Results |

Report | ||

Investor Overview Presentation December |

Presentation | ||

Investor Overview Presentation November |

Presentation | ||

Green Finance |

Framework | S&P Second Party Opinion | |

2024 Listing Prospectus |

Statement | ||

2024 H1 Results and Investor Presentation |

Report | Presentation | Webcast |

2023

2023 Annual Report |

Report | ||

Cyclyx Investment |

Announcement | Presentation | Webcast |

2023 H1 Results and Investor Presentation |

Report | Presentation | Webcast |

2022

2022 Annual Report |

Report | ||

Prospectus for Uplisting on Oslo Børs |

Document | ||

2022 H1 Results and Investor Presentation |

Report | ||

2021

2021 Annual Report |

Report | Executive Summary | |

2021 H1 Results and Investor Presentation |

Report | ||

2020

2020 Annual Report |

Report | ||

Agilyx AS Financial Statements – first half 2020 |

Statements | ||

Join our team and help us change the way the world recycles

Discover opportunities

Our mission

Use innovative technology for good and help solve the problem of plastic waste

At Agilyx, we are investing in developing systems, processes, and technology to increase plastic waste recycling and promote a circular economy for plastic, reducing our dependency on fossil fuels and our carbon footprint. As we invest and build operations and strategic partnerships around the world, we are looking for people who are equally committed to helping change the way the world recycles.

We take care of the people who make our mission possible with a comprehensive benefits package

Up to 90% company-paid medical, dental and vision insurance premiums

Company-paid life insurance

Professional development and growth opportunities

401K with company matching employee contribution up to 3%

A flexible work environment for most roles

Competitive salary

Company-paid, long-term, and short-term disability

The ability to work remotely or hybrid in many roles

Many more company-provided benefits

Our Values

At Agilyx, we are committed to living our values.

We expect our employees to embrace and reflect these values in the work that they do every day as we move forward on our mission to use technology for good and help solve the problem of plastic waste.

Be safe

Safety first and always.

Be collaborative

Be inclusive and work together in delivering quality solutions.

Be Innovative

Use our entrepreneurial passion to drive continuous improvement in our mission to end plastic waste and protect our environment.

Be Responsible

Be accountable for doing the right thing in the right way, acting with integrity, and treating others with respect.

Agilyx’s proprietary advanced recycling technology

Styrenyx

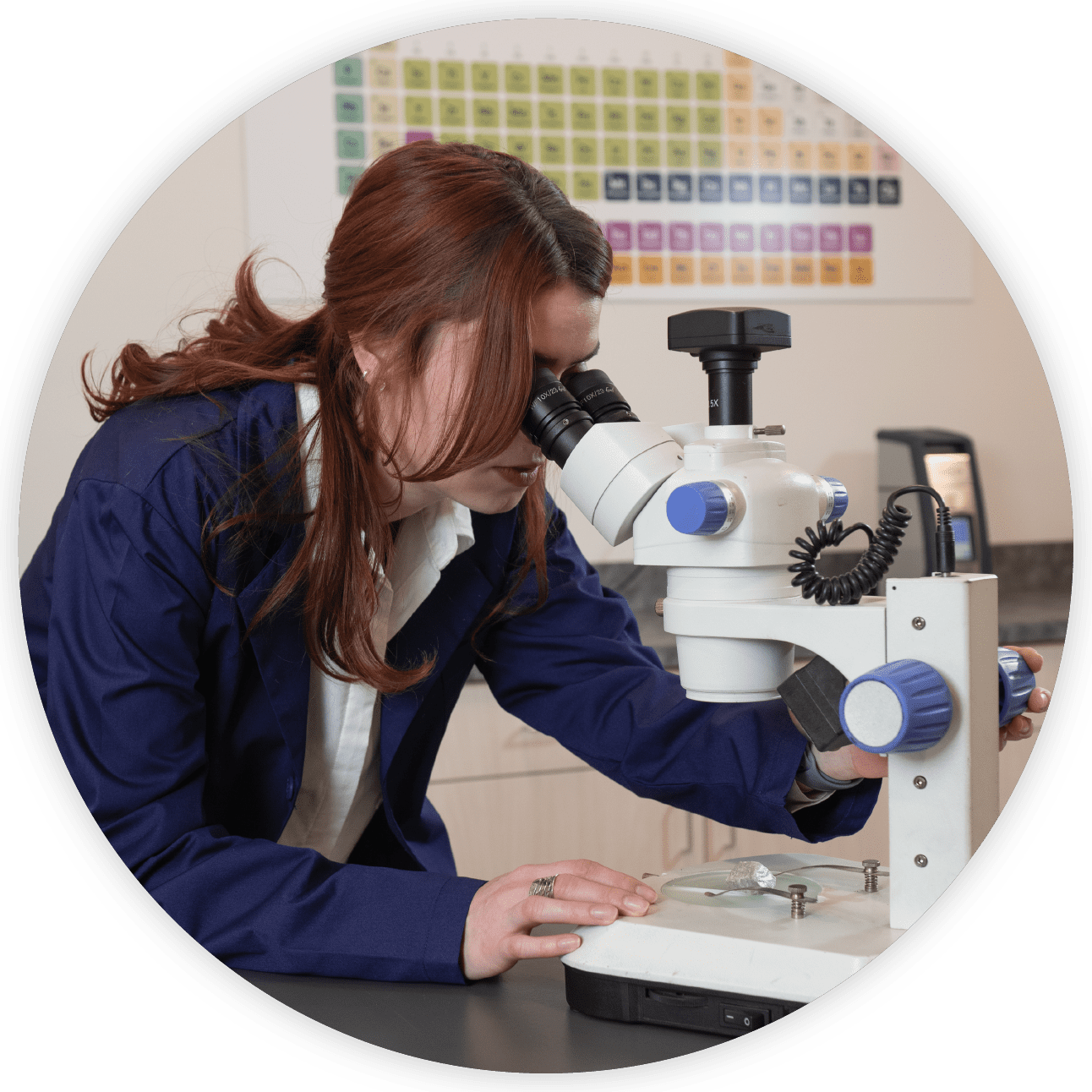

Our technology uses catalyst-free depolymerization to recycle polystyrene waste back into its virgin-equivalent building blocks for reuse in new, high-quality products. A third party reviewed report confirms that when using renewable energy to recycle polystyrene (PS) to styrene, Styrenyx can reduce up to 86% of carbon-equivalent emissions compared to fossil-based production.

Styrenyx, our advanced recycling technology, not only enables a circular economy for plastic, it does so with a lower carbon impact. Choosing innovative solutions and investing in the necessary infrastructure is essential for solving the plastic waste crisis and create a lower-carbon, more sustainable future.

Preserving the value of plastic, sustainably

Agilyx’s advanced recycling technology tackles the global plastic waste problem by processing hard-to-recycle plastics that traditional recycling methods cannot. Styrenyx, our proprietary depolymerization process, uses controlled temperatures to break polystyrene into its original building blocks, preserving their value for continuous reuse in a circular economy. Our technology supports a sustainable future by using an electrified reactor with lower carbon impact and a renewable energy source.

Our technology can reduce carbon equivalent emissions for styrene production by up to 86% compared to fossil-based production

Agilyx commissioned Sphera Solutions to conduct a cradle-to-gate carbon footprint assessment.

Lowers emissions by 86% when powered by renewable energy

Cuts CO₂ emissions by 46% using grid electricity

Consistent with ISO 14067:2018 standards

Critically reviewed by a third party

Built for versatility Styrenyx is used in commercial-scale technology platforms to redirect plastic waste from landfills and the environment back into use. Unlike other technologies, Styrenyx’s reactor does not use a catalyst. This means we are able to process even contaminated plastic waste, greatly increasing recyclability rates.

Lower-carbon process

Reduces carbon impact by using an electrified reactor powered by a renewable energy source

Catalyst-free system

Allows contaminated polystyrene feedstocks

Robust feedstock capability

Allows input of a broad range of polystyrene feedstocks and blends (including, waste PS, GPPS, EPS, XPS, HIPS, ABS, AS & SAN)

Flexible process

Reduces carbon impact by using an electrified reactor powered by a renewable energy source

Backed by 20+ years of technology development

With eight generations of technology development, a robust portfolio of patents and a license actively operating at a waste polystyrene recycling facility in Japan, Agilyx has established its leadership position in the advanced recycling industry. The technology is compatible with ISCC PLUS certification standards, enabling traceability and verification of recycled content to support customer and regulatory requirements.

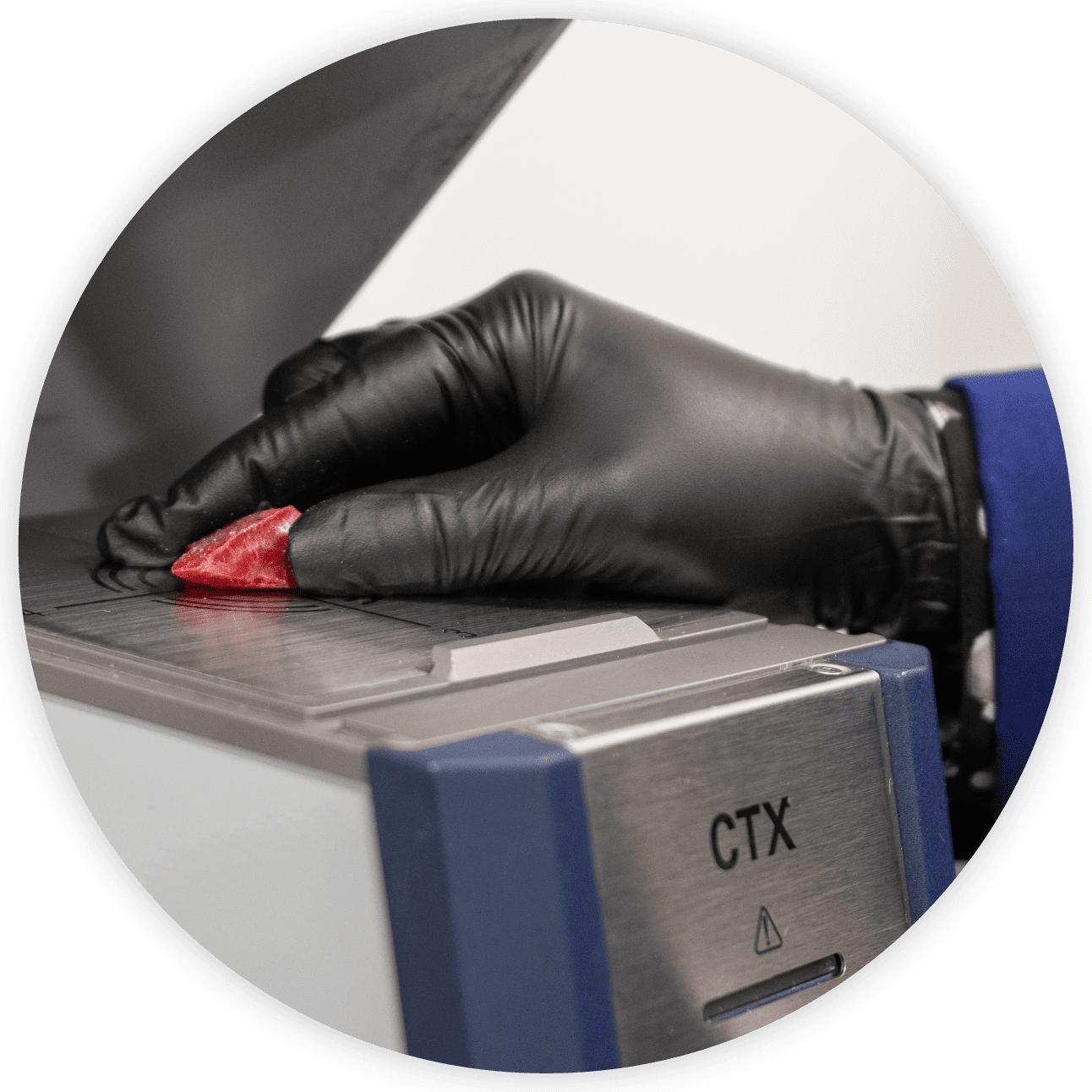

Styrenyx: Feedstock to Product

Styrenyx is designed to drive the future of sustainable packaging by enabling plastics to be recycled repeatedly, reducing reliance on fossil-based materials and significantly lowering carbon footprints.

Input: Polystyrene feedstock

Densified polystyrene waste is fed into the reactors.

Conversion: Depolymerization

Our patented pyrolysis reactor depolymerizes, (breaks down using high, controlled temperatures) the polystyrene into its original building blocks: styrene monomers.

Output: Styrene monomer

The end-product, a styrene monomer, enables all styrene monomer end-markets to create new, virgin-equivalent, high-quality polystyrene products, reducing the need for fossil-based production.

Styrenyx is proven on a commercial scale

Styrenyx is at the heart of Toyo Styrene’s advanced recycling facility in Chiba, Japan — the largest facility dedicated to the depolymerization of polystyrene waste in the country.

This innovative facility converts polystyrene waste into a styrene monomer using Styrenyx technology. The recovered styrene monomer can be used to make high-quality polystyrene products with a significantly reduced carbon footprint compared to those made with virgin materials.

In January of last year, we were very excited to announce that our polystyrene chemical recycling project with Toyo Styrene was moving into construction. A lot has happened in that time and we wanted to share our progress and provide some insight.

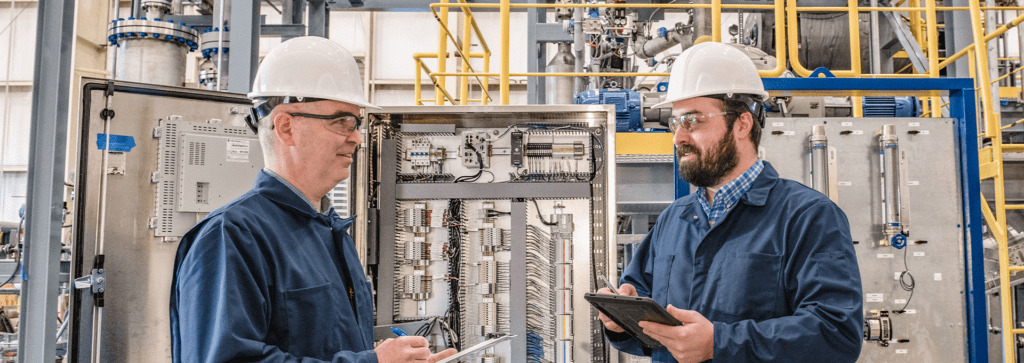

Since our previous announcement, the Agilyx team has been busy designing, specifying, procuring and fabricating equipment to complete the build out of Toyo’s new pyrolysis system.

Working at a fabrication site in Louisiana, Agilyx’s project team came together to fully build and conduct the factory acceptance test on the modular system that will power Toyo Styrene’s plant.

Over the course of several weeks, we saw the equipment modules come together and evaluated the system to be sure it met specification and will perform as designed once installed in its new home in Chiba Prefecture, Japan. Our counterparts at Toyo Styrene joined us on site to evaluate and inspect the equipment they will be installing and working together with Agilyx to commission.

Once the equipment arrives at Toyo Styrene’s location, the Agilyx and Toyo teams will work together to reassemble the 10 ton per day modules and begin the commissioning process of the new facility, which we anticipate will happen in the first quarter of 2024.

We at Agilyx could not be more pleased with our partnership with Toyo and the progress that we have made together toward creating the first polystyrene chemical recycling facility in Japan.

PORTSMOUTH, New Hampshire, USA, November 28, 2022 – Cyclyx International, a consortium-based post-use plastic innovation company with a mission to increase the recyclability of plastic from 10% to 90%, has announced the launch of a new website for its mission brand, 10 to 90®, at 10to90.com, with a focus on implementing new residential and consumer-based waste plastic takeback programs that aspire to dramatically increase the amount and types of waste plastics diverted from landfill.

The new website is designed to provide individuals with a better understanding of how recycling works and, more importantly, how their own actions can make a positive impact to increase the recyclability of waste plastics. 10 to 90® is part of a global effort to increase plastic recycling. The initial iteration of the 10to90.com website is being launched in coordination with programs that are rolling out in the Houston, Texas area as part of the Houston Recycling Collaboration, with the intention of adding more programs in the coming year that can help accelerate plastic recycling, locally in the short term with a goal to impact global recycling rates in the long term.

As previously announced, 10 to 90® is a set of takeback programs, education, rewards and engagement tools, supported by members of the Cyclyx consortium of companies, designed to incentivize small changes of behavior at home in order to increase the amount of waste plastics diverted from landfills and into the Cyclyx supply chain. Those waste plastics can then be recycled to a range of products by consortium members through mechanical and advanced recycling processes.

“We are very excited to offer this new tool to help people become better informed about the impact they can have on recycling and to help them actively participate in the 10 to 90® mission,” stated Joe Vaillancourt, CEO of Cyclyx. “People are frustrated by the complexity of the recycling systems that are in place, and the fact that most waste plastics are not actually recycled. With our 10 to 90® programs, our mission is to accept all types of plastic, regardless of the number on the bottom, with the goal of preparing it for use by our members to make new recycled products, helping us on our mission to increase the recyclability of plastic. Our goal is to mobilize residents and consumers through our 10 to 90® programs to divert more waste plastics from landfill and into the Cyclyx system. There, Cyclyx and its members can work together to help find new recycling pathways for those plastics as we strive on our mission to increase recycling rates from 10% to 90%.”

The initial launch of the 10 to 90® website includes general information on recycling, a description of future programs, a summary of how Cyclyx works and a form allowing users to be notified when programs are available in their areas. Future releases will include additional developments such as drop-off locations, educational games and the ability to enroll and participate in a rewards program allowing them to earn Virgin Points from Virgin Red.

Every long journey begins with a single step. We are taking an important step with a mission to see plastics recycling move from 10% to 90%. We hope you will join us.

Media Contact

Melissa Emmott

VP, Marketing and Programs

memmott@cyclyx.com

About Cyclyx International, LLC.

Cyclyx International, LLC. (“Cyclyx”) is a post-use plastic innovation company working with industry participants to develop innovative recycling solutions for all types of post-use plastics. The company’s mission is to increase the recyclability of plastics from 10% to 90% by using Cyclyx’s expertise in understanding the chemical composition of post-use plastic in collaboration with industry partners to create a new, innovative supply chain. Cyclyx was founded by Agilyx Corporation (“Agilyx”), a leader in advanced chemical recycling, together with ExxonMobil Chemical Company, one of the largest chemical companies in the world. Cyclyx has been formed to be a consortium-based entity and since its founding there have been a growing number of companies joining its membership. For more information, visit us at www.cyclyx.com.

- Facility will sort and process a wide range of plastic waste designed to produce 150,000 metric tons of feedstock per year for mechanical and advanced recycling

- ExxonMobil and LyondellBasell plan to invest an estimated $100 million in the facility with start-up expected in 2024

PORTSMOUTH, New Hampshire, USA, October 18, 2022 – Cyclyx International, ExxonMobil and LyondellBasell today announced they have signed an agreement to advance development of a first-of-its-kind plastic waste sorting and processing facility in the Houston area. The new facility addresses a critical missing link in the plastic waste supply chain by connecting community recycling programs to new and more advanced recycling technologies that have the potential to take a much wider variety of plastic materials.

The Cyclyx Circularity Center will be unique among plastic recovery facilities, producing feedstock for both mechanical and advanced recycling. The center will leverage new technologies to analyze plastics based on their composition and sort them according to customer specifications for their highest and best reuse.

The circularity center will be located in the Greater Houston area, with commercial start-up expected in 2024. The facility will be designed to produce 150,000 metric tons or 330 million pounds of plastic feedstock per year, supplying ExxonMobil and LyondellBasell advanced recycling projects as well as mechanical recycling markets. Total investment for the first circularity center is estimated to be $100 million, contingent upon a final investment decision in early 2023.

“To help increase the overall U.S. recycling rate and meet growing customer demand for circular products, more investment is needed by governments and industry to collect and sort waste,” said Dave Andrew, vice president of new market development at ExxonMobil. “With this new facility, we are making a substantial investment in plastic waste sorting infrastructure to accelerate our advanced recycling efforts in Baytown and along the Gulf Coast.”

“We are growing our global recycling capacity and actively pursuing opportunities to help capture more plastic waste from landfills in order to make it suitable for recycling,” said Yvonne van der Laan, executive vice president of circular and low-carbon solutions at LyondellBasell. “This agreement is a perfect example of how collaboration across the value chain can help close the gaps to make a circular economy possible, such as access to plastic waste feedstock.”

“This project serves as proof of how significant the need is for custom blended plastics feedstock,” stated Joe Vaillancourt, CEO of Cyclyx. “With our capability to accept and process a wide range of waste plastics based on their chemistry profile which we custom blend to the needs of our customers, we are creating a new set of recycling options for difficult-to-recycle waste plastics that today are sent to landfill. Our circularity centers will allow us to make available a much larger amount of waste plastic into usable feedstock than has been possible with the current recycling infrastructure. Additional circularity centers are under consideration on the Gulf Coast and other locations.”

Cyclyx, ExxonMobil and LyondellBasell are members of the Houston Recycling Collaboration whose mission is to help the City of Houston significantly increase plastic recycling rates, leveraging new technologies and infrastructure, such as this Cyclyx facility, to recycle nearly all plastics.

As of September 2022, ExxonMobil has processed more than 6,700 metric tons (nearly 15 million pounds) of plastic waste at its Baytown facility, recycling materials that may have otherwise gone to landfill or incineration. When the facility’s expansion is complete later this year, it will be among North America’s largest advanced recycling facilities, with an annual capacity to recycle 30,000 metric tons of plastic waste. Leveraging ExxonMobil’s existing manufacturing assets, plans are underway to build up to 500,000 metric tons (1 billion pounds) of annual advanced recycling capacity by year-end 2026 across multiple sites globally.

LyondellBasell has a goal to produce and market 2 million metric tons of recycled and renewable-based polymers annually by 2030. To deliver on this ambition, the company recently announced a new organizational structure including a Circular and Low-Carbon Solutions business segment and is strategically investing along the value chain.

Cyclyx has a goal of processing more than 650,000 metric tons of waste plastic per year by 2026. Consistent with this goal, Cyclyx is focused on its mission to help increase the plastics recycling rate from 10 to 90% by getting the right feed to the right technology, creating a new supply chain for waste plastic, and diverting post-use plastic from landfill.

Media Contacts

Cyclyx

Melanie Burger

Director, Corporate Communications

mburger@cyclyx.com

ExxonMobil

(972) 940-6007

LyondellBasell

mediarelations@lyb.com

+1 (713) 309-7575

About Cyclyx International, LLC.

Cyclyx International, LLC. (“Cyclyx”) is a post-use plastic innovation company working with industry participants to develop innovative recycling solutions for all types of post-use plastics. The company’s mission is to increase the plastic recycling rate from 10% to 90% by using Cyclyx’s expertise in understanding the chemical composition of post-use plastic in collaboration with industry partners to create a new, innovative supply chain. Cyclyx was founded by Agilyx Corporation (“Agilyx”), a leader in advanced chemical recycling, together with ExxonMobil, one of the largest chemical companies in the world. Cyclyx has been formed to be a consortium-based entity and since its founding there have been a growing number of companies joining its membership. For more information, visit us at www.cyclyx.com.

Follow us on LinkedIn.

About ExxonMobil

ExxonMobil, one of the largest publicly traded international energy and petrochemical companies, creates solutions that improve quality of life and meet society’s evolving needs. The corporation’s primary businesses – Upstream, Product Solutions and Low Carbon Solutions – provide products that enable modern life, including energy, chemicals, lubricants, and lower-emissions technologies. ExxonMobil holds an industry-leading portfolio of resources, and is one of the largest integrated fuels, lubricants and chemical companies in the world. To learn more, visit exxonmobil.com and the Energy Factor.

Follow us on Twitter and LinkedIn.

About LyondellBasell

As a leader in the global chemical industry, LyondellBasell strives every day to be the safest, best operated and most valued company in our industry. The company’s products, materials and technologies are advancing sustainable solutions for food safety, access to clean water, healthcare and fuel efficiency in more than 100 international markets. LyondellBasell places high priority on diversity, equity and inclusion and is Advancing Good with an emphasis on our planet, the communities where we operate and our future workforce. The company takes great pride in its world-class technology and customer focus. LyondellBasell has stepped up its circularity and climate ambitions and actions to address the global challenges of plastic waste and decarbonization. In 2022, LyondellBasell was named as one of FORTUNE Magazine’s “World’s Most Admired Companies” for the fifth consecutive year. For more information, please visit www.lyondellbasell.com or follow @LyondellBasell on LinkedIn.

Forward-Looking Statement for LyondellBasell

The statements in this release relating to matters that are not historical facts are forward-looking statements. These forward-looking statements are based upon assumptions of management which are believed to be reasonable at the time made and are subject to significant risks and uncertainties. Actual results could differ materially from the projections, anticipated results, or other expectations expressed in this release, including, but not limited to, the final investment decision related to the proposed facilities; the successful construction and operation of the facilities described in this release; the ability to obtain all necessary regulatory approvals; our ability to meet our sustainability goals, including the ability to increase production of recycled and renewable-based polymers to meet our targets and forecasts; and general economic conditions in geographic regions or markets served by LyondellBasell and its affiliates, or where operations of the company and its affiliates are located. While these statements and projections are made in good faith, LyondellBasell and its management cannot guarantee that anticipated future results will be achieved. Additional factors that could cause results to differ materially from those described in the forward-looking statements can be found in the “Risk Factors” section of our Form 10-K for the year ended December 31, 2021, which can be found at www.lyondellbasell.com on the Investor Relations page. LyondellBasell assumes no obligation to publicly update or revise any forward-looking statements made herein or any other forward-looking statements made, whether as a result of new information, future events, or otherwise.

PORTSMOUTH, New Hampshire, USA, October 17, 2022 – Cyclyx International, a consortium-based post-use plastic innovation company with a mission to increase the recyclability of plastic from 10% to 90%, announced that Ron Sherga has joined the business as Vice President of Member Engagement, effective today.

Ron will be broadly responsible for developing the strategies and execution plans for the expansion of the Cyclyx member consortium as well as the various business development and engagement opportunities that could be possible with the growing membership.

Ron brings a wealth of experience to the role, with over 35 years of experience as an advisor, inventor and executive, advancing large scale projects and strategies related to recycling, energy recovery and sustainable solutions. Ron has one issued patent and another filed targeted at the tracking and monetizing of polymers for credits and offsets.

“I am pleased and excited to become a part of the leadership team at Cyclyx,” stated Mr. Sherga. “Cyclyx and their partners have demonstrated amazing growth and vision in addressing solutions to plastic waste. I look forward to helping play a role in future success, strategies and expansion.”

“I am happy to welcome Ron to Cyclyx,” stated Joe Vaillancourt, CEO of Cyclyx. “His extensive experience across functions and deep understanding of circular economy strategies and sustainability in the plastics and waste industries make Ron a wonderful addition to our leadership team.”

Ron will be based in Arlington, Texas.

About Cyclyx International, LLC.

Cyclyx International, LLC. (“Cyclyx”) is a post-use plastic innovation company working with industry participants to develop innovative recycling solutions for all types of post-use plastics. The company’s mission is to increase the recyclability of plastics from 10% to 90% by using Cyclyx’s expertise in understanding the chemical composition of post-use plastic in collaboration with industry partners to create a new, innovative supply chain. Cyclyx was founded by Agilyx Corporation (“Agilyx”), a leader in advanced chemical recycling, together with ExxonMobil Chemical Company, one of the largest chemical companies in the world. Cyclyx has been formed to be a consortium-based entity and since its founding there have been a growing number of companies joining its membership. For more information, visit us at www.cyclyx.com.

Public support for recycling is nearly universal, yet today the U.S. is recycling less than it did in 2018. Only six percent of all plastic was recycled last year. This comes despite widespread attention on the vast amount of waste plastic that ends up in landfills and the ocean, harming wildlife and the environment.

The decline in plastic recycling makes no sense given widespread support but is easily explained: the recycling infrastructure in the U.S. is broken. If we want to recycle more and waste less, the country needs a completely new system to get the job done.

Adding to the challenge: consumers are not well informed about what plastics can and cannot be recycled, what steps to take to recycle, and where to do so. We need education, awareness and convenient support systems to help households and communities make more plastic recycling possible.

Another issue with our current recycling system is access and investment. Recycling is a service that competes with local government funds for education, health and housing.

Recently, the U.S. EPA announced $375 million for recycling, reuse and waste prevention programs. That is a major down payment, but it will take years and many billions of new infrastructure investment dollars to change the system to have the desired impact.

The good news is there are technologies to recycle nearly all plastics. Leveraging traditional methods, such as mechanical recycling, and newer technologies, known as chemical recycling, there is almost no plastic we cannot recycle. This includes the hard-to-recycle plastic that currently ends up in landfills.

But before we get to the recycling process, we need to change how we manage the stream of plastic waste, so that plastic waste can be used as feedstock, or source material, for the production of new virgin-equivalent plastics.

Today, the recycling systems for plastic is not adequate to increase the recycling options for low grade plastics. As a result, most plastic waste never has a chance of being recycled, and thus industry continues to make new virgin materials for the manufacture of plastics.

What’s missing is a system that diverts all plastic waste from landfills and a means to sort and identify the various recycling options and outlets where the plastic waste can be channeled.

Without this, our collective recycling efforts are more feel-good efforts than effective, and we will never be able to significantly increase the recyclability of plastic waste. If managed properly, plastic waste can be a meaningful resource for our industrial economy with positive impacts to our environment.

Cyclyx, the company I am proud to lead, has developed a real-world solution. We have combined technical know-how, new supply chains, the design and development of new and unique processing facilities and a consortium-based business model to bring real change to the plastic recycling industry.

To fill the missing link in the system, Cyclyx is partnering with many companies across a broad set of industries and communities to access and capture all kinds of plastic waste, much of which is currently deemed non-recyclable. From there, we combine the power of our plastic characterization data, predictive modeling and unique recipe compounding to understand the composition of the plastic waste streams and identify the appropriate recycling outlet.

The access to plastic waste our consortium provides, combined with our innovative capabilities to analyze large volumes of plastic waste, allows us to divert more waste from landfills and into their best use, bridging the gap between recycling and waste management efforts – and bringing us one step closer to closing the loop on recycling and transforming plastic waste into an impactful resource.

Our goal is to recycle 90 percent of waste plastics. We recently launched an exciting effort, 10 to 90®, a series of new take-back, education and engagement programs designed to divert more low-quality plastic waste from landfills into our system, where they can be recycled and turned back into valuable products.

10 to 90 will be rolled out in collaboration with cities, retail establishments, corporations and universities in an effort to improve access and increase the recycling rate at the community level. If we can accelerate plastic recycling at the local level, we can raise recycling rates at the global level, improving the environment for all.

We can’t wait any longer for today’s outdated infrastructure to catch up. Scalable solutions like ours will enable change toward ending the global plastic waste crisis.