OSLO, Norway – March 24th, 2025 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”) announces the launch of Plastyx Ltd. in collaboration with Carlos Monreal. Plastyx aims to be Europe’s leading feedstock supplier to the advanced plastic recycling market. Plastyx Ltd. is a 60:40 joint venture between Agilyx and Circular Resources SARL. Mr. Monreal will serve as Chairman.

While advanced plastic recycling technologies are scaling industrially and complementing mechanical recycling, the industry’s growth remains constrained by the availability of consistent, high-quality feedstock. Plastyx is designed to bridge this gap by developing partnerships and material processing capabilities to ensure a reliable supply of high-quality polymers for food-grade and other high-performance packaging applications. The company´s near-term objective is to source and execute MOUs for 200,000 metric tons of waste plastic by the end of 2025.

“I am excited to start this new phase. After developing advanced recycling facilities as chairman and CEO of Plastic Energy and investing in recycling collection programs through my investment in GreenDot, the natural, next step is to focus on feedstock sourcing. Partnering with Agilyx provides a unique opportunity to scale our joint vision,” said Carlos Monreal.

“Agilyx is committed to building an international sourcing platform to support our interests in Cyclyx,” added Ranjeet Bhatia, Chief Executive Officer of Agilyx. “Carlos is a leader in our field and has unparalleled understanding of the advanced recycling industry. By linking Cyclyx’s industry-leading feedstock management capabilities with Plastyx, through Agilyx’s shared ownership interest, we are launching an exciting first mover in this critical market segment.”

For more information, visit www.agilyx.com and www.plastyx.com

Investors go to: Sustainable investment opportunity | Agilyx innovative solutions

For inquiries contact: investors@agilyx.com

Agilyx ASA is at the forefront of plastic waste recycling, enabling the conversion of challenging post-use plastics into high-value, virgin-equivalent products. Recognizing that availability of high-quality, custom feedstock is critical for scaling recycling processes, Agilyx, through its Cyclyx and Plastyx joint ventures, provides tailored feedstock solutions to global plastic producers. In addition, Agilyx leverages its Styrenyx technology platform and T.EN’s purification technology to market TruStyrenyx – a full polymer-to-monomer

advanced recycling solution for polystyrene. By advancing from a linear “make-take-waste” model to a sustainable circular economy, Agilyx supports the transition to a low-carbon future. Our adaptable approach ensures bespoke solutions, leveraging extensive IP and feedstock expertise to meet diverse customer needs.

OSLO, Norway – March 20th, 2025 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”) announces that production of styrene via Styrenyx, its proprietary polystyrene recycling technology, significantly reduces carbon equivalent emissions compared to producing styrene from fossil resources.

To better assess the carbon footprint of our advanced recycling, post-consumer waste circular styrene production, Agilyx commissioned Sphera Solutions, Inc. to perform a cradle-to-gate product carbon footprint (PCF) and compare results to conventional production of styrene from fossil resources. Results indicate that Agilyx’s process lowers carbon equivalent emissions by 38% using average grid electricity and 86% using wind electricity as compared to conventional styrene made from fossil resources. The study has been conducted according to the requirements of the International Organization for Standardization (ISO) 14067:2019-02 (ISO, 2019) and is currently undergoing independent critical review by 3rd party expert, in accordance with ISO/TS 14071:2014 (ISO, 2024). The expert review is expected to be complete in Q2 2025.

For context, these results indicate that an Agilyx facility producing 18,000 metric tons of styrene annually and powered by grid electricity could reduce the equivalent of ~15,000 metric tons of CO2 emissions compared to conventional styrene. This is equivalent to removing ~3,500 gasoline cars off the road for a year (~6.4 million litres /1.7 million gallons of gasoline) or the amount of CO2 sequestered by 245,000 tree seedlings over a decade (US EPA, 2024). Global production of styrene is projected to reach 16.75 million tonnes by 2026. If 10% of this volume were produced using Styrenyx, it would be the equivalent to removing 325,000 gasoline cars from the road annually.

“We are extremely encouraged by these results and remain committed to further reducing our carbon footprint” said Chris Faulkner, Chief Technology Officer of Agilyx. “By leveraging sustainable energy sources and innovative recycling technologies, we will reduce global carbon emissions and help solve the plastic waste challenge.”

About Agilyx

Agilyx ASA is at the forefront of plastic waste recycling, enabling the conversion of challenging post-use plastics into high-value, virgin-equivalent products. Recognizing that availability of high-quality custom feedstock is critical for scaling recycling processes, Agilyx, through its Cyclyx joint venture, provides tailored feedstock solutions to global plastic producers. In addition, Agilyx leverages its Styrenyx technology platform and T.EN’s purification technology to market TruStyrenyx – a full polymer-to-monomer advanced recycling solution for polystyrene. By advancing from a linear “make-take-waste” model to a sustainable circular economy, Agilyx supports the transition to a low-carbon future. Our adaptable approach ensures bespoke solutions, leveraging extensive IP and feedstock expertise to meet diverse customer needs. For more information, visit Agilyx’s corporate website www.agilyx.com

For investor inquiries contact: communications@agilyx.com

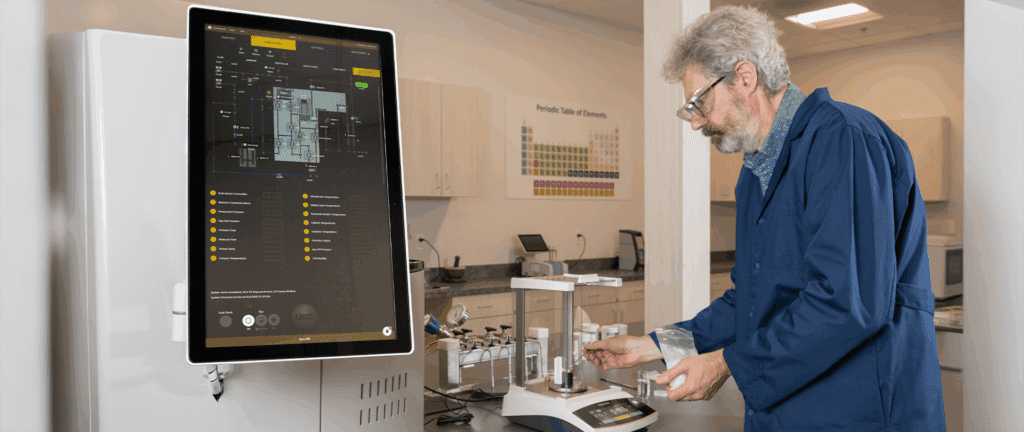

Agilyx Research Center – The ARC

Agilyx brings more than 20 years of expertise in analyzing the chemical complexity of plastic waste. This knowledge enables us to transform hard-to-recycle plastics into valuable resources instead of becoming waste.

Services we provide

The ARC provides a range of services including characterization and identification of plastic streams that can be turned into feedstock sources matched to advanced recycling processes. Projects range from small-scale lab, through pilot plan, to full-scale identification and design of commercial facilities.

Expertise in chemical characterization of plastic waste

Using our extensive polymer and mixed polymer expertise (including co-polymers, binders, multi-layers), plastic sources can be matched to provide rapid turnaround of suggested pathways. Follow-up with physical characterization, pilot-scale processing, pre and post-processing treatment and sample generation provide data that can be used as design input for full-scale process design projects.

Helping our customers recycle plastic waste

Do you have waste or a hard-to-recycle plastic?

Do you want to investigate the potential pathways to turning that material into useful products via advanced recycling?

Do you want to do a feasibility study for recycling of large volumes of material?

We can create a custom project plan to match your requirements and budget from “Can I recycle this material?” to “I want to build a large commercial facility” and all points in-between.