Latest Innovation Demonstrates Agilyx’s Commitment to Technological Advancement

OSLO, Norway, March 24, 2021 – Agilyx AS (Euronext Growth (Oslo): (“AGLX”), a pioneer in the advanced recycling of post-use plastics, announced today that the European Patent Office (EPO) has issued a decision to grant a patent for the proprietary process for polishing Agilyx Synthetic Crude Oil (“ASCO”). The patent – EP2981593 – underscores Agilyx’s commitment to bringing its technological expertise and IP knowledge to the European market.

The newly patented process optimizes the removal of contaminants from ASCO with the use of proprietary equipment. ASCO is the product of Agilyx’s advanced recycling conversion process, which is delivered to customers as the building block for the manufacture of circular plastics. The resulting purer form of ASCO maximizes its compatibility with existing refining processes, while minimizing the damaging effects of contaminants on refinery equipment.

Commenting on the granting of the patent, Chris Faulkner, chief technology officer at Agilyx stated: “This new European patent yet again demonstrates our expertise in the advanced recycling of plastics and commitment to reducing plastic waste. Our technology offers a genuine pathway for plastic circularity and enables our vision of increasing the recycling of plastics.”

This latest patent is the result of specialist in-house research and development, reflecting the deep technical know-how and commercial scale operations that Agilyx has built upon since the company was founded. The patent highlights Agilyx’s significant experience in the industry of advanced recycling, converting mixed post-consumer plastics to high quality products.

Agilyx

Kate Ringier

VP, Communications & Government Affairs

+41 78 822 7770

kate.ringier@agilyx.com

About Agilyx

Agilyx (AGLX), is a pioneer in the advanced recycling of difficult-to-recycle post-use plastic streams. With Agilyx’s chemical recycling technology and intelligent feedstock management system, mixed plastic waste can be converted to new virgin-equivalent plastics, as well as chemical products and fuels – creating the opportunity for true circularity. The company has not only developed these first-to-market products but has also developed a feedstock management company Cyclyx International, Inc. and is working with many waste service providers, municipalities, petrochemical, and brand and retail companies to develop closed-loop advance recycling solutions for mixed waste plastics. Contact us to have your plastic waste streams recycled at info@agilyx.com. For more information, follow us on social media and visit us at www.agilyx.com.

Recovering the value of plastic waste by transforming it into premium feedstock for sustainable solutions

Cyclyx is on a mission to increase the recyclability of post-use plastics, regardless of origin, composition, or condition by delivering high-quality feedstock from materials once considered unrecyclable.

From collection to new, virgin-equivalent material

Expanded collection

Cyclyx’s systems accept difficult-to-recycle plastics, like plastic films, flexibles, and multi-laminates, recovering more plastic, more effectively—turning waste into value at scale.

Innovative systems

Using proprietary technology and advanced sorting capabilities, Cyclyx can analyze, blend, and custom-formulate recycled feedstock to meet customer specifications. Solutions are innovative and data-driven.

Feedstock to product

ISCC-PLUS certified feedstock is converted into valuable, lower-carbon material that can be used in the production of new plastics and products that make modern life possible.

353 million tons of plastic waste generated yearly, less than 10% is recycled*

One of the biggest barriers to plastic recycling is lack of feedstock from plastic waste.

The lack of high-quality feedstock is a major industry bottleneck that curtails the potential of increased advanced recycling capacity

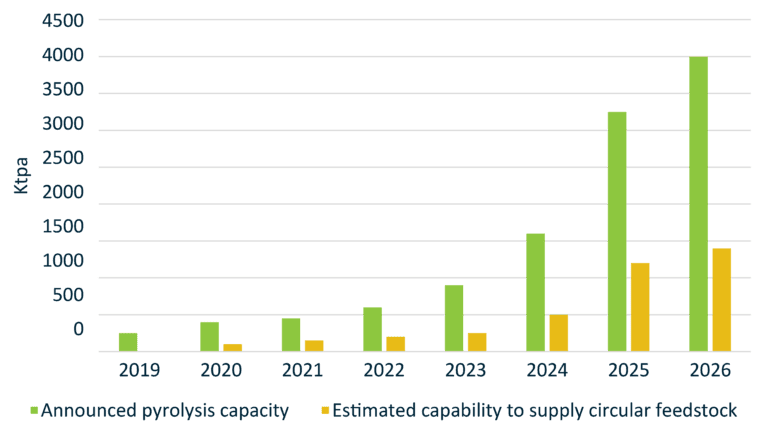

Supply of plastic feedstock lags existing pyrolysis capacity by an estimated 60%*. Innovative post-use plastic sourcing, sorting, and characterization are needed to meet feedstock demand.

The industry struggles with the management and infrastructure necessary to deliver the right type of feedstock to those who can recycle it best.

Cyclyx was formed to address one of the toughest challenges in recycling today: how to efficiently manage plastics that traditional systems can’t process.

Chart: Wood Mackenzie

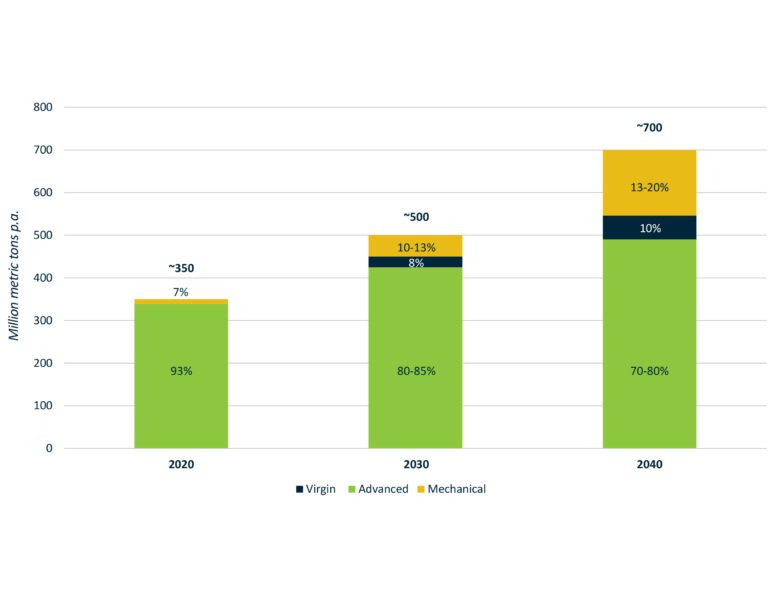

Projected demand for recycled material is increasing, creating a significant opportunity for Cyclyx Circularity Centers to provide plastic waste feedstock

Near term, feedstock demand and investment in innovative recycling solutions are forecasted to grow at record pace.

By 2030, an estimated 67 MM tons p.a. of incremental processing capacity will be required to supply sufficient feedstock to the recycling industry. Meeting this demand underscores the need for hundreds of plastic processing facilities across the U.S. and globally.

What is a

Cyclyx Circularity Center?

Cyclyx Circularity Centers are first-of-their-kind facilities capable of accepting a wide range of post-consumer, commercial, and industrial plastic waste and custom-formulating it into ISCC-PLUS-certified feedstock for mechanical and advanced recycling applications.

Learn more about Cyclyx

ExploreAppointment underlines commitment to transform the plastic recycling supply chain

PORTSMOUTH, New Hampshire, USA, March 19, 2021 – Cyclyx International, a feedstock management company co-founded by Agilyx Corporation and ExxonMobil, announced today the appointment of Kevin Paine as Vice President of Finance – Business Partner. Mr. Paine joined Cyclyx on March 1 and will support the growth of the organization through strategic and business development efforts.

In his new role, Mr. Paine will bring his in-depth knowledge of the waste management sector to develop strategic growth and business development opportunities. Mr. Paine will also work to increase membership of the consortium-based organization from the whole spectrum of stakeholders in the plastic recycling industry. He will collaborate with partners to develop recycling solutions for all types of plastic waste.

“We are excited to welcome Kevin, who brings nearly 30 years of experience in waste management, to the team. Kevin’s expertise will be integral to advancing the growth of the organisation whose ultimate aim is to increase the recyclability of plastics,” stated Joe Vaillancourt, Cyclyx CEO.

Mr. Paine brings a multifaceted knowledge of the waste management sector. Mr. Paine joins Cyclyx from Waste Management (WM) where he most recently served as Director of Operations Analysis for WM’s organics recycling business. Mr. Paine previously held management roles focused on both consumer-facing and waste-to-value businesses, including plastics-to-oil and municipal waste-to-fuel conversion technologies.

About Cyclyx International, LLC.

Cyclyx International, LLC. (“Cyclyx”) is a post-use plastic feedstock management company working with industry participants to develop recycling solutions for all types of post-use plastics. The company’s mission is to increase the recyclability of plastics by using Cyclyx’s expertise in understanding the chemical composition of waste plastic in collaboration with industry partners to create a new, innovative supply chain. Cyclyx was founded by Agilyx Corporation (“Agilyx”), a leader in advanced chemical recycling, and joined by ExxonMobil Chemical Company, one of the largest chemical companies in the world, to help address the complexities of recycling post-use plastics. For more information, visit us at www.cyclyx.com.

Contacts:

Kate Ringier

VP, Communications & Government Affairs +41 78 822 7770

kate.ringier@agilyx.com

Glossary

A primer to the recycling industry and the Agilyx ecosystem

Glossary

Advanced recycling

Advanced recycling – also known as chemical, molecular or feedstock recycling – refers to the sophisticated technologies used to convert post-use plastics (polymers) back to their original chemical building blocks (monomers) for continued reuse. As the only recycling process that makes plastic a circular resource, advanced recycling is critical to solving the problem of plastic waste and enabling the world’s transition to a low-carbon economy.

Circular economy

The circular economy describes a more sustainable economic system that is based on the “reduce-reuse-recycle” principle. Unlike the “take-make-waste” linear economy, circularity is considered essential to addressing climate change, better managing the world’s resources and achieving the UN Sustainable Development Goals.

EPR

EPR stands for Extended Producer Responsibility and is an environmental policy approach where a producer is responsible for the entire life cycle of its product, from creation to disposal, in order to meet legal obligations. Under EPR, producers are responsible for designing products with materials that have the lowest possible environmental impact and are optimized for recycling. The producer is also responsible for the post-use collection and treatment of its products with a focus on recycling

ESG

This abbreviation stands for the range of environmental, social and governance criteria used to evaluate the sustainability performance of a company or business and determine its level of financial risk. ESG factors play an increasingly important role for investors in both the public and private markets.

Feedstock

A feedstock is a single and uniform raw material that is used to drive an industrial process or act as fuel. Post-use plastic feedstocks can be used to create virgin-equivalent plastic, as well as plastic intermediates or other valued low-carbon products.

ISCC PLUS Certification

This independent and internationally recognized certification system, used to verify the allocation of recycled content in a manufacturer’s product, was developed by the International Sustainability & Carbon Certification. ISCC PLUS certification ensures a company’s compliance with sustainability and traceability requirements along the supply chain.

Mass balance

In short, mass balance is used to calculate and confirm the recycled content in a given product. It enables the tracking of recycled material throughout the industrial process, allowing the manufacturer or brand owner to claim how much of the final product can be attributed to recycled content. Third-party certification by recognized institutions, such as the ISCC, is critical in determining the accuracy of mass balance claims.

Mechanical recycling

According to Plastics Europe, mechanical recycling refers to the processing of plastics waste into secondary raw material or products without significantly changing the chemical structure of the material. Because the plastic is downgraded into lower-quality plastic with each cycle, it eventually winds up in landfills or the environment, and is therefore not circular.

Pathway

The pathway is the general term used to describe a more sustainable use of post-use plastic, rather than disposal in landfills or the environment. Agilyx has created commercial plastic-to-plastic pathways for polystyrene, with others underway.

Plastic-to-plastic recycling

This process involves using advanced recycling technology to break post-use plastic down into its original chemical components, which are fed back into the manufacturing process to create new, equally recyclable plastics. At a commercial scale, plastic-to-plastic recycling is the only way to turn plastic into a circular resource and exponentially increase global recycling rates.

Plastic intermediate

Plastic or chemical intermediates refer to base products that require additional steps prior to use in the production of new plastics. They do not include the direct monomers needed to produce new polymers.

Post-use plastics

Post-use plastics – also called post-consumer or waste plastics – are the used plastic products that are collected as part of waste management systems. They are either recycled or disposed of, winding up in landfills or the environment.

Pyrolysis

Pyrolysis describes the process of using heat to decompose materials and change their chemical composition. Agilyx uses an IP-protected pyrolysis technology which, in the absence of oxygen, breaks down the polymer chains without combustion (and its associated by-products).

Styrene monomer

A raw material used to create numerous plastic products and synthetic rubber. Agilyx uses an IP-protected pyrolysis technology to break down the polymer chains of multiple types of post-consumer plastics back into its original styrene building block enabling the recycling into new products again and again.

Our commitment

Work towards a sustainable future

We are committed to help solve the problem of plastic waste. Our solutions can aid the transition to a circular economy for plastics and to a lower-carbon future.

Divert plastics from landfills and create a circular economy

Through Cyclyx, our joint venture with ExxonMobil (25%) and LyondellBasell (25%), Agilyx supports the development and implementation of innovative plastic waste solutions that divert plastics from landfills and the environment and reintroduce them to the economy as valuable, premium feedstock for recycling technologies.

Our advanced recycling technology can promote circularity and reduce carbon-equivalent emissions

Styrenyx, Agilyx’s advanced recycling technology, can reduce carbon equivalent emissions for styrene production by up to 86% compared to fossil-based production. This recycling technology plays a fundamental role in reducing our customers’ environmental impact, supporting business model changes and enabling plastic circularity.

Styrenyx, Agilyx’s advanced recycling technology, can reduce carbon equivalent emissions for styrene production by up to 86% compared to fossil-based production. This recycling technology plays a fundamental role in reducing our customers’ environmental impact, supporting business model changes and enabling plastic circularity.

Continuously work toward sustainability

We are constantly evaluating and integrating our sustainable practices as an essential part of our company climate roadmap.

Technology design

Continuous, measurable improvement

in carbon reduction potential

Collaboration

Cascading sustainable business practices with the companies we work with

Engineering

Joint carbon management programs with

customers and value chain

Active contribution to the UN Sustainable Development Goals

By transforming plastic from a linear to a circular model, Agilyx actively contributes to five of the 17 UN Sustainable Development Goals and indirectly contributes to two more.

#8 DECENT WORK AND ECONOMIC GROWTH

Through our initiatives and joint ventures, Agilyx supports valuable “green jobs” that are helping shape a better future for our economy and our world.

#9 INDUSTRY, INNOVATION AND INFRASTRUCTURE

Through investments in innovative recycling solutions and infrastructure, Agilyx is working to make post-use plastic management systems more circular and recover the value of plastic over and over again.

#11 SUSTAINABLE CITIES AND COMMUNITIES

Cyclyx engages with waste management authorities and municipalities, advocating for greater investment in recycling infrastructure.

#12 RESPONSIBLE CONSUMPTION AND PRODUCTION

Agilyx directly supports reducing waste generation through prevention, reduction, recycling and reuse.

#13 CLIMATE ACTION

Advanced technologies like Styrenyx reduce society’s reliance on fossil fuels and support the transition to a lower carbon future. Plastics made from recycled feedstock have a lower greenhouse gas footprint than traditional plastics made from below ground fossil sources, such as oil and natural gas.

Agilyx has identified two additional SDGs that our value chain partners support through the adoption of Agilyx technology, enabling more circular and sustainable pathways:

#14 LIFE BELOW WATER

Diverting plastic waste from landfills and to feedstock processing facilities contributes to this goal by reducing plastic pollution in our oceans and waterways.

#15 LIFE ON LAND

Agilyx is enabling efforts to reduce plastic pollution on land by supporting the creation of pathways to divert plastic waste from landfills and into feedstock processing facilities, promoting a circular economy with lower CO2 emissions.

Investors

From feedstock management to advanced recycling technology, Agilyx invests in solutions across the value chain that help shift our world from a linear, “make-take-waste” economy, to a more sustainable “retrieve-restore-recycle” one. Agilyx is committed to help solve the crisis of plastic waste and support the transition to a low-carbon future by making plastic a truly circular resource.

Analyst Coverage

Discover analysts monitoring our performance

General Meeting

Minutes and notices from our general meetings

Investor Relations

Our team is here to help

Share Information

Shares trading on the Oslo Stock Exchange and OTCQX Best Market

Corporate Governance

Our foundation for financial integrity and sustainable performance

Financial Calendar

Key dates for the financial calendar

Top Shareholders

The top 20 Agilyx ASA shareholders by shares, country, and history

LEADING THE WAY

A team of experts committed to change

The Agilyx team is made up of technologists, chemical engineers, manufacturing specialists and experienced business leaders from the chemical and waste management industries

Ranjeet Bhatia

Ranjeet Bhatia

Chief Executive Officer

Bertrand Laroche

Bertrand Laroche

Chief Financial Officer

Chris Faulkner, Ph.D

Chris Faulkner, Ph.D

Chief Technology Officer

Jessica Fletcher

Jessica Fletcher

Vice President of Engineering and Project Management

Alex de Geofroy

Alex de Geofroy

Vice President of Information Technology and Analytics

Peter Norris

Peter Norris

Chair of the Board

Carolyn Clarke

Carolyn Clarke

Chair of Audit Committee

Steen Jakobsen

Steen Jakobsen

Chair of Compensation Committee

Catherine C. Keenan

Catherine C. Keenan

Chair of Sustainability Committee

Our investments in innovative solutions contribute to a lower-carbon future and help solve the problem of plastic waste

Our Mission

Use innovative technology for good and help solve the problem of plastic waste

Big problems require BIG SOLUTIONS

While we agree that plastic waste is a huge global challenge, its recycling rates are currently less than 10%. This is due to outdated industry infrastructure and management processes that result in the majority of plastics ending up in landfills, incinerators and, worst of all, the environment.

This must change.

Agilyx’s investments support innovations that help recover the value of plastic waste

Implementing recycling solutions reclaims plastic’s value and gives it a new, circular life. By expanding the range of recyclable plastics and increasing waste collection, sorting, and processing, we can enable plastic circularity. Our goal is to play a crucial role in recovering the value of “above-ground” hydrocarbons and accelerate the transition to a lower-carbon economy.

Locations

office

The Agilyx Research Center and Headquarters

7370 SW Durham Road

Tigard, OR, 97224

office

European Office

plant

Toyo Styrene’s Polystyrene Recycling Facility – Employing Styrenyx

Chiba, Japan

Cyclyx Circularity Center 1

Houston, Texas

Under Construction

Cyclyx Circularity Center 2

Dallas, Fort-Worth, Texas

Under construction

Commitment to collaboration

No one can solve this enormous problem alone. As we tackle the complex challenges of managing plastic waste across the value chain, the need for collaboration has never been greater. By fostering a synergetic working environment with our employees, partners, customers, and communities, together we can drive this much needed change!

A primer to the recycling industry and the Agilyx ecosystem

The recycling industry is full of challenges and opportunities. From feedstock supply to advanced recycling technology, opportunities to create value are there. This quick primer breaks down the basics and explains how Agilyx fits into the picture. From sourcing plastics to converting them into high-quality materials, explore how our ecosystem is helping drive real progress and value in plastic circularity.

INNOVATORS FROM THE START

Driven by technology, expertise and purpose

Sustainable by design

Agilyx was founded in 2004 to help solve a pressing global issue: plastic waste.

We have since driven innovative solutions across the value chain by launching joint ventures Cyclyx and Plastyx to scale the production of high-quality feedstock, developing our advanced recycling technology for polystyrene waste, Styrenyx, and reimagining business models to accelerate global change.

2025

The Agilyx Research Center (the ARC) is open for operation. Our state-of-the-art R&D lab is dedicated to developing sustainable solutions for plastic waste that support the move towards plastic circularity.

2025

Agilyx launches Plastyx Ltd. to source and supply feedstock for the European advanced plastic recycling industry

2024

Powered by Styrenyx, Agilyx’s proprietary depolymerization technology, Japan’s largest advanced recycling facility for polystyrene waste is operational.

2022

Agilyx listed on the main list of the Oslo Stock Exchange.

2022

Agilyx and Technip Energies’ launch TruStyrenyx, an all-in-one technology platform for the advanced recycling of polystyrene.

2021

Cyclyx International, a post-use plastic-to-feedstock innovator, is launched with ExxonMobil as a joint venture partner.

2020

Agilyx listed on the Merkur Market, part of the Oslo Stock Exchange (now EuroNext Growth).

ISCC PLUS certification received for fully circular pathway for polystyrene recycling.

2013-2014

TSCA registration received from US EPA for Agilyx Synthetic Crude Oil (ASCO), and 8 million pounds of mixed waste plastics are processed.

2010-2012

Generation 4 and 5 technology released and business grows to commercial deployment.

2007-2008

Generation 2 and 3 technology released.

2006

Development of Generation 1 technology and oil production breakthrough.

2004

Agilyx founded in Longview, Washington (US) as Plas2Fuel.

Discover our solutions

Small title

Title

Agilyx delivers technology-based solutions at their best. Our commercial-scale platforms redirect hard-to-recycle plastics from waste streams, converting them into valuable, low-carbon products. Through our licensing model, companies all over the world can do the same.

CEO

- The agreement concerns Agilyx’s pyrolysis advanced technology to convert mixed waste plastics into high-value circular products and fuels

- NextChem will act as technology, and Engineering, Procurement, and Construction (EPC) partner on a series of projects

OSLO, Norway – Milan, Italy, March 15, 2021 ─ Agilyx Corporation, a wholly owned subsidiary of Agilyx AS (Euronext Growth (Oslo): “AGLX”), a pioneer in the advanced recycling of post-use plastics and NextChem, subsidiary of Maire Tecnimont Group, have entered into an agreement to support the development of advanced chemical recycling facilities globally. This agreement combines Agilyx’s leading pyrolysis technology with NextChem’s expertise, as a leader in licensing, implementation, and EPC services for plastics recycling solutions.

Under the agreement, NextChem will act as a technology and EPC partner for Agilyx. The aim of this partnership is to accelerate the implementation of chemical recycling facilities globally, utilizing Agilyx advanced pyrolysis technology in the conversion of mixed waste plastic into circular olefins and circular fuels. With a longstanding expertise in the advanced recycling of plastics, Agilyx’s proprietary chemical recycling process can turn post-use plastics back into their original chemical components for continued use, increasing the recovery of plastics that cannot be recycled with traditional recycling processes.

The scope of the partnership, in its first phase, is to develop a series of chemical recycling projects for third parties. The initial focus will be on two already identified projects, one in Europe and one in South America. Furthermore, the agreement would represent an opportunity for co-investments in specific projects in order to accelerate the overall commercial pipeline.

“We are proud to include this new partnership with Agilyx into our portfolio and further develop our basket of technological solutions for the circular economy, that already include Upcycling, waste to chemicals, waste to fuels, polymerization and now also thermochemical conversion (pyrolysis). We are strongly committed to finding solutions for plastics sustainability along its life-cycle and to enabling a new circular, low carbon economy,” commented Pierroberto Folgiero, CEO of Maire Tecnimont Group and NextChem.

“This alliance represents an acceleration for Agilyx to expand our footprint and implement our advanced recycling technology globally,” said Tim Stedman, Agilyx CEO. “NextChem is a global leader in the deployment and realization of projects and technologies for energy transition and circular economy and we are pleased to be partnering with them to accelerate our go to market strategy as we seek to expand our technology licensing.”

About Maire Tecnimont Group

Maire Tecnimont S.p.A., listed on the Milan Stock Exchange, heads an industrial group which leads the global natural resource conversion market (downstream oil & gas plant engineering, with technological and executive expertise). Its subsidiary NextChem operates in the field of green chemicals and technologies in support of the energy transition. The Maire Tecnimont Group operates in approx. 45 countries, though approx. 50 operative companies and about 9,100 people. For further information: www.mairetecnimont.it www.nextchem.com

Group Media Relations

Carlo Nicolais, Tommaso Verani

+39 02 63137603

mediarelations@mairetecnimont.it

Investor Relations

Riccardo Guglielmetti

Tel +39 02 6313-7823

investorrelations@mairetecnimont.it

Communication Manager NextChem

Ilaria Catastini

+39 06 93567718 – +39 327 0663447

mediarelations@nextchem.itAbout Agilyx

Agilyx (AGLX), is a pioneer in the advanced recycling of difficult-to-recycle post-use plastic streams. With Agilyx’s chemical recycling technology and intelligent feedstock management system, mixed plastic waste can be converted to new virgin-equivalent plastics, as well as chemical products and fuels – creating the opportunity for true circularity. The company has not only developed these first-to-market products but has also developed a feedstock management company Cyclyx International, Inc. and is working with many waste service providers, municipalities, petrochemical, and brand and retail companies to develop closed-loop advance recycling solutions for mixed waste plastics. www.agilyx.com.

Agilyx

Kate Ringier

VP, Communications & Government Affairs

+41 78 822 7770

Kate.Ringier@agilyx.com

Mr. de Geofroy is the Vice President of Information Technology and Analytics at Agilyx. Mr. de Geofroy has over 15 years of engineering, technology, and management experience in R&D and manufacturing, including roles at GE Plastics (now SABIC), Lockheed Martin Space Systems, and Safran Aerospace, among others. Mr. de Geofroy specializes in developing high performance technical teams, with an emphasis on data, analytics, and AI/ML; digital transformation and enterprise architecture; internal software development; and cybersecurity. He earned his Bachelor of Science in Electrical Engineering and his MBA from the University of Massachusetts Amherst.

Mr. de Geofroy served for nine years as an officer in the Army National Guard in both command and staff roles ranging from infantry platoon leader to aviation company commander. Outside Agilyx, he engages in civic and community activities, including serving multiple terms as both a city councilor and elections official in Rochester, New Hampshire. Mr. de Geofroy also volunteers for political committees and non-profits throughout the state, providing pro bono tech and analytics consulting. He is a member of the US Global Leadership Coalition, a national non-profit organization that advocates for increased support for diplomatic and development efforts.