Local recycling program launched to help reduce landfill waste by recycling polystyrene foodservice containers that are helping prevent the spread of COVID-19

Portland, Ore., June 05, 2020 – Agilyx Corporation (“Agilyx”), the leader in chemical recycling of post-use plastics back into polymers, chemicals and low carbon fuels, today announced the collaboration with Beaverton Lodge, an Oregon Metro area retirement residence, to recycle polystyrene foodservice items. Beaverton Lodge recently implemented a polystyrene foodservice program to reduce the potential for exposure of residents and staff to the COVID-19 virus.

The Beaverton Lodge, which on average serves 200 meals per day to their 150 residents, had previously provided the majority of their meals through a community dining room with delivered meals provided for residents if needed. In January of 2020 they implemented a new program in response to initial concerns for the safety of their residents. To limit any unintended transmission of COVID-19, the community dining room was closed and replaced with a direct meal delivery program using Dart Container polystyrene foodservice containers. Polystyrene was chosen for the new program due to the need for insulated, cost-effective, single-use items to transport prepared meals from the kitchen to the residents.

After starting this new program, Beaverton Lodge began collecting the used foodservice items and deliver them to Agilyx in Tigard, Oregon. The collected polystyrene items will then be recycled to new products through Agilyx’s joint venture with Americas Styrenics, Regenyx. By doing this, Beaverton lodge is helping to divert foodservice items from being landfilled and is helping to create polystyrene items with up to 70% less Greenhouse Gas generation (“GHG”) as compared to virgin materials. To ensure the safety of Agilyx employees, materials that are received from this program will be quarantined for three days to mitigate any potential transmission while preparing the feedstock.

“Agilyx is proud to be working with an organization that is pioneering new, environmentally-sustainable projects, meeting zero-waste goals and maximizing the wellbeing of their residents and staff,” stated William Cooper, SVP of Corporate Strategy at Agilyx Corporation. “We hope that programs like this can help educate others in the industry about the benefits and circular recyclability of single-use plastics.”

“We have always strived to be green and established recycling at our facility early on, before most places like ours had recycling,” said Ian “Louie” Paul, Executive Director of Beaverton Lodge. “It has been a challenge adapting to the ‘new normal’, but our residents and staff have all gone above and beyond to make sure everyone stays healthy. Together, we can get through this.”

About Beaverton Lodge

Beaverton Lodge is a 62+ Independent Living Community. We pride ourselves on providing affordable luxury to our residents. Family built and owned since 1987. We are close to many public amenities, yet maintain a relaxed, comfortable, and quiet location. For more Information, visit us at www.beavertonlodge.com.

OSLO, Norway – October 16th, 2025 – Agilyx ASA (OSE: AGLX: OTCQX: AGXXF: ISIN:NO0010872468: WKN: A2QGQ) (“Agilyx” or the “Company”) references the announcement made by the Company on July 17, 2025 regarding a binding and fully financed agreement to acquire 44% of GreenDot Global S.à r.l. (“GreenDot”), a transformative investment that significantly strengthens Agilyx’s presence in the European market, creating a global platform for sourcing and supplying feedstock to the advanced recycling industry, and announces that the transaction has been completed.

Following approval at the Extraordinary General Meeting held on October 3rd 2025, all conditions for the closing of the GreenDot transaction were satisfied. Closing took place on October 15th 2025, at which time and after a capital increase in GreenDot, Agilyx owns approximately 44% of all issued shares in GreenDot, a pan-European circular recycling platform for waste plastic feedstock. The acquisition transaction included Agilyx contributing EUR 7m to a EUR 27m investment round into GreenDot.

GreenDot is working towards expanding its reach in the mechanical recycling sector while continuing to advance contracts to supply advanced recycling feedstock and remaining focused on the growth of its profitable core business in Germany´s plastic recycling market – a business on track to generate circa EUR 400m in 2025 sales. In September, GreenDot was awarded a 10-year feedstock supply contract from a third-party advanced recycling facility, representing 20,000-34,000 tons per annum. The company has also entered into an agreement to purchase a mechanical recycling facility in Italy, which specializes in bottle-to-bottle recycling and the production of pipes from recycled material.

Agilyx CEO Ranjeet Bhatia commented, “We are pleased to reach completion on the GreenDot investment. We have a tremendous opportunity to rapidly build the leading pan-European plastic recycling platform and are very much looking forward to working with our new GreenDot colleagues and shareholders to achieve our goals.”

GreenDot CEO Laurent Auguste comments, “We are very glad to welcome Agilyx as a new GreenDot shareholder. This new capital injection will support our facility expansion in Germany, Austria, and Italy, further propelling GreenDot’s commitment to scaling the European circular economy of plastic. The synergies between two market leaders that this investment creates strengthen our ability to act as a preferred partner of global brands and actors in the plastic packaging value chain.”

Inquiries: investors@agilyx.com

Learn more at: www.agilyx.com

For media resources, visit: https://www.agilyx.com/media-room/

About Agilyx

Agilyx ASA is a leading global investment platform supporting the development of plastic waste feedstock supply to the recycling industry. Through its 44% stake in GreenDot Global, Europe’s largest waste plastic recycling platform, generating over EUR 400 million in annual revenues, Agilyx gains access to large volumes of post-use plastic and advanced sorting and recycling infrastructure in Germany, Austria, and Italy, helping supply critical European-sourced feedstock to the European advanced recycling markets. Through Cyclyx, its (50%) joint venture with ExxonMobil (25%) and LyondellBasell (25%), Agilyx supports the collection and processing of post-use plastic waste into custom-formulated, high-quality feedstock solutions for global plastic producers. Agilyx markets Styrenyx, its proprietary advanced recycling technology, to recycle polystyrene waste into recycled styrene monomers for reuse in new, high-quality products. By enabling the shift from a linear “make-take-waste” model to a circular economy, Agilyx helps solve the crisis of plastic waste and supports the global transition to a low-carbon future.

OSLO, Norway – August 18, 2025 – Agilyx ASA (OSE: AGLX: OTCQX: AGXXF: ISIN: NO0010872468: WKN: A2QGQ) (“Agilyx” or the “Company”), announces a third-party reviewed Product Carbon Footprint report of Styrenyx, Agilyx’s proprietary recycling technology, shows CO2 emissions can be cut by up to 86% by using depolymerization of waste polystyrene compared to fossil production.

To better assess the carbon footprint of Styrenyx, our advanced recycling, post-consumer waste circular styrene production, Agilyx commissioned Sphera Solutions, Inc. to perform a cradle-to-gate product carbon footprint (PCF) consistent with ISO 14067:2018 standards, and compare results to conventional production of styrene from fossil resources. As announced in March 2025, the results have now been reviewed by a third party, confirming that when Styrenyx uses renewable energy to recycle polystyrene (PS) to styrene, it can reduce up to 86% of carbon-equivalent emissions compared to fossil-based production. At minimum, Styrenyx can save 46% carbon-equivalent emissions when powered by a standard electrical grid. This is higher than the 38% savings originally reported in March 2025.

“Our advanced recycling technology not only enables a circular economy for plastic, it does so with lower-carbon impact. Investing in and choosing innovative solutions for plastic waste is essential for building the infrastructure needed for a lower-carbon, more sustainable future, and helps solve the plastic waste crisis”, said Chris Faulkner, Chief Technology Officer of Agilyx.

Download the full report by visiting our website: https://www.agilyx.com/styrenyx/

Inquiries: investors@agilyx.com

Learn more at: www.agilyx.com

For media resources, visit: https://www.agilyx.com/media-assets/

Stay in the loop by following our Linkedin company page.

ABOUT AGILYX

Agilyx ASA is a leading global investment platform supporting the development of plastic waste feedstock supply to the recycling industry. Through its 44% stake in GreenDot Global, Europe’s largest waste plastic recycling platform, generating over EUR 400 million in annual revenues, Agilyx gains access to large volumes of post-use plastic and advanced sorting and recycling infrastructure in Germany, Austria, and Italy, helping supply critical European-sourced feedstock to the European advanced recycling markets. Through Cyclyx, its (50%) joint venture with ExxonMobil (25%) and LyondellBasell (25%), Agilyx supports the collection and processing of post-use plastic waste into custom-formulated, high-quality feedstock solutions for global plastic producers. Agilyx markets Styrenyx, its proprietary advanced recycling technology, to recycle polystyrene waste into recycled styrene monomer for reuse in new, high-quality products. By enabling the shift from a linear “make-take-waste” model to a circular economy, Agilyx helps solve the crisis of plastic waste and supports the global transition to a low-carbon future

Tags:

OSLO, Norway – July 17, 2025 – Agilyx ASA (OSE: AGLX: OTCQX: AGXXF) (“Agilyx” or the “Company”) has entered into a binding and fully financed agreement to acquire 44% of GreenDot Global S.à r.l. (“GreenDot”). This transformative investment significantly strengthens Agilyx’s presence in the European market, creating a global platform for sourcing and supplying feedstock to the advanced recycling industry.

GreenDot is the leading circular plastic recycling platform in Europe and the third-largest recycling company in Germany. Licensed across 29 countries, it is the most recognized recycling brand in Europe. GreenDot processes more than 1 million tons of packaging waste annually, including over 400,000 tons of plastic. The company is expanding its advanced recycling feedstock supply capabilities by investing in sorting facilities in Austria and Italy. For 2025, GreenDot’s operations are expected to generate approximately EUR400 million in total sales and double-digit EBITDA.

Ranjeet Bhatia, CEO of Agilyx, commented:

“We are thrilled to expand Agilyx´s reach into Europe as we build a global platform to supply feedstock to the plastic recycling industry. GreenDot is the recognized industry leader in Europe, has tremendous momentum in the fast-developing advanced recycling market, and is a great complement to Agilyx’s existing activities. We´re looking forward to working closely with GreenDot´s talented management and world-class shareholders on this transformative opportunity.”

Laurent Auguste: CEO of GreenDot commented:

“We very much welcome Agilyx as a new GreenDot shareholder. Agilyx’s investment and the business synergies we will develop between two market leaders across the Atlantic will strengthen our ability to act as a preferred partner of brands and actors in the plastic packaging value chain. The new capital injection will support expansion of facilities in Germany, Austria, and Italy and is additional evidence of GreenDot’s commitment to scaling the circular economy of plastic in Europe.”

The transaction values GreenDot at a post-money enterprise value of EUR197 million. Agilyx will acquire its 44% stake for a total consideration of EUR52 million consisting of approximately EUR32 million in newly issued Agilyx shares (“Consideration Shares”), priced at the 30-day-volume-weighted average price (VWAP) of 25.76 NOK per share, and approximately EUR20 million in cash in a combination of primary and secondary share purchases. The Consideration Shares will be subject to a lock-up period until 10 January 2026 followed by a 90-day window during which sales by the sellers will be capped at 20% of the prior 30-day average daily trading volume.

The transaction is fully financed by certain existing investors through a EUR20 million subordinated loan facility. The loan facility will rank subordinated to Agilyx’s outstanding bonds issued under “Agilyx ASA 13.50% senior secured USD 50,000,000 bonds 2024/2027” and is subject to a subordinated loan agreement to be entered into with the bond trustee, as set out in the bond terms. The transaction is expected to close in late Q3 2025, subject to customary conditions including, inter alia: regulatory approval under German foreign direct investment laws, lender consent for change of control at GreenDot, and Agilyx shareholder approval for the issuance of the Consideration Shares at an Extraordinary General Meeting (EGM), for which sufficient voting undertakings have been received.

Further information can be found in the file attached to this announcement and on the Agilyx website.

In connection with this transaction, Tor Svelland will step down from Agilyx’s Nomination Committee. The Company intends to nominate Tom Lileng as his replacement, subject to approval at the upcoming EGM. Mr. Lileng brings extensive investment and governance experience. He served most recently as Managing Director of General Oriental Investments and Cavamont Holdings, where he managed both liquid and private investment portfolios, achieving strong absolute and risk-adjusted returns. He currently serves as a Non-Executive Director and Nomination Committee Member for two other publicly listed Norwegian companies.

ABOUT AGILYX

Agilyx ASA is at the forefront of advanced recycling, converting post-use plastics into high-value feedstock and virgin-equivalent products. Through Cyclyx, its joint venture with ExxonMobil (25%) and LyondellBasell (25%), Agilyx supports the collection and processing of post-use plastic waste into custom-formulated, high-quality feedstock solutions for global plastic producers. Through Plastyx, its joint venture with Circular Resources (40%), Agilyx provides critical European-sourced feedstock to the global mechanical and advanced recycling markets. Additionally, Agilyx markets TruStyrenyx, a polystyrene advanced recycling solution that combines its Styrenyx depolymerization technology with Technip Energies’ purification process. By advancing from a linear “make-take-waste” model to a circular economy, Agilyx supports the transition to a low-carbon future.

ABOUT GREENDOT

GreenDot brings nearly three decades of experience in the circular economy and deep commercial relationships with global brands such as Nestle, PepsiCo, and Mondelez, providing a unique end-to-end food packaging solution to brand owners. Its close cooperation with Agilyx will significantly enhance Agilyx’s long-term feedstock strategy and capacity to scale advanced plastic recycling solutions, creating a unique global platform for waste plastic feedstock to meet rapidly increasing demand for high-quality feedstock.

***

This information is considered to be inside information pursuant to the EU Market Abuse Regulation (MAR) and is subject to the disclosure requirements pursuant to MAR article 17 and section 5-12 of the Norwegian Securities Trading Act. This stock exchange announcement was published by Ana Sandersen, Marketing and Corporate Affairs Manager of the Company, on 17 July 2025 at 01:42 hours CEST.

Important information

This announcement is not and does not form a part of any offer to sell, or a solicitation of an offer to purchase, any securities. The distribution of this announcement and other information may be restricted by law in certain jurisdictions. Persons into whose possession this announcement or such other information should come are required to inform themselves about and to observe any such restrictions. Copies of this announcement are not being made and may not be distributed or sent into any jurisdiction in which such distribution would be unlawful or would require registration or other measures.

Matters discussed in this announcement may constitute forward-looking statements. Forward-looking statements are statements that are not historical facts and may be identified by words such as “believe”, “expect”, “anticipate”, “strategy”, “intends”, “estimate”, “will”, “may”, “continue”, “should” and similar expressions. The forward-looking statements in this release are based upon various assumptions, many of which are based, in turn, upon further assumptions. Although Agilyx believe that these assumptions were reasonable when made, these assumptions are inherently subject to significant known and unknown risks, uncertainties, contingencies and other important factors which are difficult or impossible to predict, and are beyond their control. Such risks, uncertainties, contingencies and other important factors could cause actual events to differ materially from the expectations expressed or implied in this release by such forward-looking statements Agilyx does not make any guarantee that the assumptions underlying the forward-looking statements in this announcement are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this announcement or any obligation to update or revise the statements in this announcement to reflect subsequent events. You should not place undue reliance on the forward-looking statements in this announcement. The information, opinions and forward-looking statements contained in this announcement speak only as at its date, and are subject to change without notice. Agilyx do not undertake any obligation to review, update, confirm, or to release publicly any revisions to any forward-looking statements to reflect events that occur or circumstances that arise in relation to the content of this announcement.

This announcement is for information purposes only and is not to be relied upon in substitution for the exercise of independent judgment. It is not intended as investment advice and under no circumstances is it to be used or considered as an offer to sell, or a solicitation of an offer to buy any securities or a recommendation to buy or sell any securities of Agilyx.

Agilyx ASA (OSE: AGLX: OTCQX: AGXXF) announces its venture Plastyx Ltd. has reached 75% of its near-term objective to source and execute MOUs for 200,000 metric tons of waste plastic by the end of 2025. As of today, it has executed MOUs for 150,000 tons.

At this rate, Plastyx is likely to double its target and help advanced recycling growth by developing partnerships and material processing capabilities to ensure a reliable supply of high-quality polymers for food-grade and other high-performance packaging applications.

Agilyx ASA is at the forefront of advanced recycling, converting post-use plastics into high-value feedstock and virgin-equivalent products. Through Cyclyx, its joint venture with ExxonMobil (25%) and LyondellBasell (25%), Agilyx supports the collection and processing of post-use plastic waste into custom-formulated, high-quality feedstock solutions for global plastic producers. Through Plastyx, its joint venture with Circular Resources (40%), Agilyx provides critical European-sourced feedstock to the global mechanical and advanced recycling markets. Additionally, Agilyx markets TruStyrenyx, a polystyrene advanced recycling solution that combines its Styrenyx depolymerization technology with Technip Energies’ purification process. By advancing from a linear “make-take-waste” model to a circular economy, Agilyx advances the transition to a low-carbon future.

Be a part of the solution.

Contact us:

investors@agilyx.com

contact@plastyx.com

Learn more at:

www.agilyx.com

www.plastyx.com

April 24, 2025

A letter from our CEO

Dear Stakeholder,

2024 was a transformative year for Agilyx. In June, we made a significant strategic shift from being primarily a developer of proprietary catalyst-free depolymerization technology to an investment holding company. Our focus is to maximize the potential of waste plastic feedstock management and custom formulations through Cyclyx, and of advanced polystyrene recycling technology with Styrenyx. This new direction aligns with our commitment to enable plastic circularity on a global and commercial scale while accelerating the shift to a low-carbon economy. For more than 20 years, Agilyx has been at the forefront of advanced recycling, pioneering technologies that have reshaped the industry. With 22 patents and a series of industry firsts, we have developed an unparalleled understanding of post-use plastic chemistry, contamination impacts, and the complexities of diverse waste streams.

Cyclyx customized feedstock: The cornerstone of recycling

Recognizing feedstock availability’s critical role in the recycling effort, our renewed focus centers on Cyclyx, our joint venture with ExxonMobil (25%) and LyondellBasell (25%) dedicated to increasing the recyclability of plastic waste by custom formulating it into valuable feedstock for new products. Through our extensive experience in waste characterization and handling contamination, we have developed an unmatched ability to optimize feedstock streams for diverse advanced and mechanical recycling technologies. This expertise positions us to address the critical industry bottleneck: the consistent supply of high-quality recycled plastic feedstock. Cyclyx is an essential bridge between waste producers and recyclers, ensuring that plastic waste is collected and inputs tailored to industrial needs.

Styrenyx advanced recycling: Recovering the value of plastic

Styrenyx, our proprietary depolymerization process enables polystyrene to be recycled repeatedly, reducing reliance on virgin resources and significantly lowering carbon footprints.

The year in brief

This year, Cyclyx continued to progress development of the Cyclyx Circularity Centers. The final investment decision for the second center, to be located in the Dallas-Fort Worth area, was taken in late 2024, marking a major milestone in the expansion of recycling infrastructure. Like the first center in Houston, this center is designed to process plastic waste into custom feedstock for recycling. Together with ExxonMobil and LyondellBasell, Agilyx invested $135 million in its development, with Agilyx’s $67.5 million pro-rata stake fully financed through equity and green bond transactions. Together, both Circularity Centers will have the capacity to produce an estimated 300,000 metric tons of feedstock annually, further strengthening our role in the circular plastics economy. We are also excited to have achieved the start of operations at Toyo Styrene’s (a member of the Denka group) facility in Japan. This facility showcases the latest generation of Styrenyx technology, highlighting our progress in scaling solutions for the circular economy. Learnings and successes over the years have played a critical role in demonstrating that advanced recycling of polystyrene is both feasible, as evidenced by facilities like Toyo, and essential to this global shift. Financially, we have reinforced our position through strategic capital raises, including a $40 million equity private placement in August and a $50 million senior secured green bond in November. Together, the raises provide the necessary resources to support the development of Cyclyx’s second Circularity Center and other corporate initiatives. Finally, we are very pleased to have launched our latest initiative, Plastyx—a 60/40 joint venture between Agilyx ASA and Circular Resources SARL. Plastyx is establishing sourcing supply chains in Europe to supply advanced recycling feedstocks to a wide range of customers, including working in close partnership with Cyclyx to support its inbound plastic demand.

Looking ahead

Our goal is clear: bridge the gap between waste producers and advanced recyclers, ensuring a steady supply of high-quality, process-ready feedstock. By supplying feedstock derived from post-use plastic and developing and marketing innovative, advanced recycling technology, we are driving meaningful change in the industry. With a strong and growing opportunity to deliver additional post-use plastic processing centers, Agilyx is poised to redefine the future of plastic recycling. As we embark on this new chapter, I want to thank our shareholders, partners, and employees for their continued support. Together, we are using technology for good, building a circular economy for plastics by turning waste into value.

Ranjeet Bhatia

Chief Executive Officer of Agilyx

OSLO, Norway – March 24th, 2025 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”) announces the launch of Plastyx Ltd. in collaboration with Carlos Monreal. Plastyx aims to be Europe’s leading feedstock supplier to the advanced plastic recycling market. Plastyx Ltd. is a 60:40 joint venture between Agilyx and Circular Resources SARL. Mr. Monreal will serve as Chairman.

While advanced plastic recycling technologies are scaling industrially and complementing mechanical recycling, the industry’s growth remains constrained by the availability of consistent, high-quality feedstock. Plastyx is designed to bridge this gap by developing partnerships and material processing capabilities to ensure a reliable supply of high-quality polymers for food-grade and other high-performance packaging applications. The company´s near-term objective is to source and execute MOUs for 200,000 metric tons of waste plastic by the end of 2025.

“I am excited to start this new phase. After developing advanced recycling facilities as chairman and CEO of Plastic Energy and investing in recycling collection programs through my investment in GreenDot, the natural, next step is to focus on feedstock sourcing. Partnering with Agilyx provides a unique opportunity to scale our joint vision,” said Carlos Monreal.

“Agilyx is committed to building an international sourcing platform to support our interests in Cyclyx,” added Ranjeet Bhatia, Chief Executive Officer of Agilyx. “Carlos is a leader in our field and has unparalleled understanding of the advanced recycling industry. By linking Cyclyx’s industry-leading feedstock management capabilities with Plastyx, through Agilyx’s shared ownership interest, we are launching an exciting first mover in this critical market segment.”

For more information, visit www.agilyx.com and www.plastyx.com

Investors go to: Sustainable investment opportunity | Agilyx innovative solutions

For inquiries contact: investors@agilyx.com

Agilyx ASA is at the forefront of plastic waste recycling, enabling the conversion of challenging post-use plastics into high-value, virgin-equivalent products. Recognizing that availability of high-quality, custom feedstock is critical for scaling recycling processes, Agilyx, through its Cyclyx and Plastyx joint ventures, provides tailored feedstock solutions to global plastic producers. In addition, Agilyx leverages its Styrenyx technology platform and T.EN’s purification technology to market TruStyrenyx – a full polymer-to-monomer

advanced recycling solution for polystyrene. By advancing from a linear “make-take-waste” model to a sustainable circular economy, Agilyx supports the transition to a low-carbon future. Our adaptable approach ensures bespoke solutions, leveraging extensive IP and feedstock expertise to meet diverse customer needs.

OSLO, Norway – March 20th, 2025 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”) announces that production of styrene via Styrenyx, its proprietary polystyrene recycling technology, significantly reduces carbon equivalent emissions compared to producing styrene from fossil resources.

To better assess the carbon footprint of our advanced recycling, post-consumer waste circular styrene production, Agilyx commissioned Sphera Solutions, Inc. to perform a cradle-to-gate product carbon footprint (PCF) and compare results to conventional production of styrene from fossil resources. Results indicate that Agilyx’s process lowers carbon equivalent emissions by 38% using average grid electricity and 86% using wind electricity as compared to conventional styrene made from fossil resources. The study has been conducted according to the requirements of the International Organization for Standardization (ISO) 14067:2019-02 (ISO, 2019) and is currently undergoing independent critical review by 3rd party expert, in accordance with ISO/TS 14071:2014 (ISO, 2024). The expert review is expected to be complete in Q2 2025.

For context, these results indicate that an Agilyx facility producing 18,000 metric tons of styrene annually and powered by grid electricity could reduce the equivalent of ~15,000 metric tons of CO2 emissions compared to conventional styrene. This is equivalent to removing ~3,500 gasoline cars off the road for a year (~6.4 million litres /1.7 million gallons of gasoline) or the amount of CO2 sequestered by 245,000 tree seedlings over a decade (US EPA, 2024). Global production of styrene is projected to reach 16.75 million tonnes by 2026. If 10% of this volume were produced using Styrenyx, it would be the equivalent to removing 325,000 gasoline cars from the road annually.

“We are extremely encouraged by these results and remain committed to further reducing our carbon footprint” said Chris Faulkner, Chief Technology Officer of Agilyx. “By leveraging sustainable energy sources and innovative recycling technologies, we will reduce global carbon emissions and help solve the plastic waste challenge.”

About Agilyx

Agilyx ASA is at the forefront of plastic waste recycling, enabling the conversion of challenging post-use plastics into high-value, virgin-equivalent products. Recognizing that availability of high-quality custom feedstock is critical for scaling recycling processes, Agilyx, through its Cyclyx joint venture, provides tailored feedstock solutions to global plastic producers. In addition, Agilyx leverages its Styrenyx technology platform and T.EN’s purification technology to market TruStyrenyx – a full polymer-to-monomer advanced recycling solution for polystyrene. By advancing from a linear “make-take-waste” model to a sustainable circular economy, Agilyx supports the transition to a low-carbon future. Our adaptable approach ensures bespoke solutions, leveraging extensive IP and feedstock expertise to meet diverse customer needs. For more information, visit Agilyx’s corporate website www.agilyx.com

For investor inquiries contact: communications@agilyx.com

Products & Services

Plastic waste solutions

From feedstock management to advanced recycling technology, Agilyx helps solve the problem of plastic waste by investing in solutions that help shift our world from a linear, “make-take-waste” economy, to a more sustainable “retrieve-restore-recycle” economy, aiding the transition to a lower-carbon future.

Our Solutions

Cyclyx

A pioneer and key enabler for the recycling industry, converting post-use plastic waste into high-quality feedstock

Styrenyx

Agilyx’s proprietary advanced recycling technology for polystyrene waste, available for licensing and equipment sourcing

TruStyrenyx

Polystyrene waste to styrene monomer platform combining Styrenyx depolymerization and Technip Energies’ purification technologies

Our Services

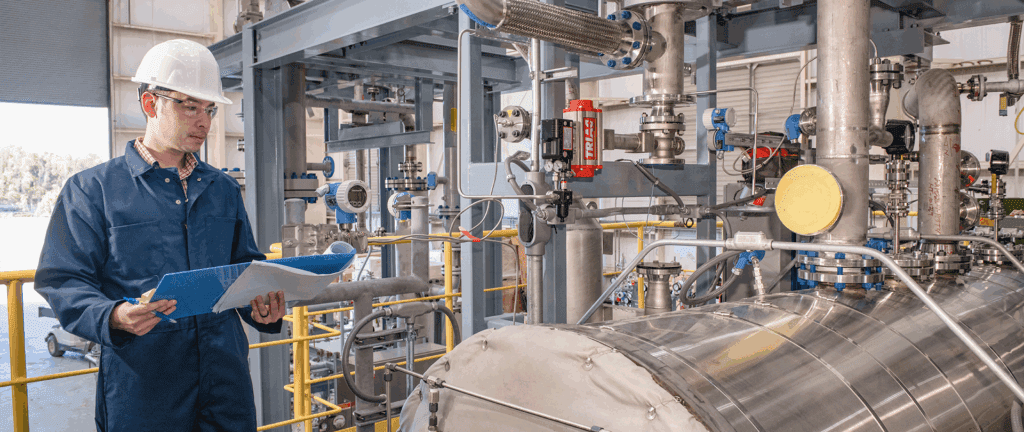

Agilyx’s technical services leverage decades of expertise in chemical technology to deliver innovative, scalable solutions for plastic waste. From process design to operator training, our team provides the technical knowledge and support needed to optimize recycling systems and drive circularity.

Agilyx Research Center Services

The Agilyx Research Center (the ARC) provides a range of services to characterize and identify plastic streams that could be turned into feedstock sources and match those to advanced recycling processes. Projects can range from small-scale lab, through pilot plant to full-scale identification and design of commercial facilities.

Rapid matching using our extensive

feed-to-product expertise

Bench & pilot-scale advanced depolymerization

Feed, product and by-product physical and chemical analysis

Feed characterization services

Generation of multi-liter quantities of products for evaluation purposes

Packaged Feasibility Studies

Detailed feedstock specification definition

Providing Experimental Data Inputs for scale-up & commercial designs

Pre- and post-process treatment

Technical Collaborations

Includes R&D design and technical services – from a process design package (PDP) to detailed design, integration, permitting support, and other project support needs

Equipment Supply

Agilyx will source, sell and supply all necessary equipment for our depolymerization process, including our proprietary pyrolysis reactor and oil conditioning system

Commissioning Services

Services to commission the supplied core equipment, provide integration support,

and basic operational training

Operator Training Program

We offer a comprehensive “train-the-trainer” program to ensure customers produce the maximum value from the process

With decades of expertise in plastics and advanced recycling, Agilyx has developed a deep understanding of the chemical complexity of plastic waste. Our knowledge drives innovation, enabling scalable solutions that transform plastic waste into valuable resources.

Dr. Chris Faulkner, Chief Techology Officer

To solve the plastic recycling problem, collaboration is key Across the value chain, Agilyx excels as a collaborator in solving the plastic waste problem. We understand that recycling is never a one-size-fits-all solution. Our flexible approach allows us to tailor solutions for our customers’ specific needs.

Make an inquiry

Across the value chain, Agilyx excels as a collaborator in solving the plastic waste problem. We understand that recycling is never a one-size-fits-all solution. Our flexible approach allows us to tailor solutions for our customers’ specific needs.

Why invest in Agilyx?

Agilyx is a publicly traded, technology-agnostic leader in the plastic recycling sector, trusted by blue-chip partners. We present a strong, diversified-exposure investment opportunity in the advanced recycling industry with funded projects that promote future growth and present a clear path to profitability.

Agilyx at a glance

A publicly traded company

Listed on the Oslo Stock Exchange (OSE) since September 2022, with a market capitalization* of NOK 2.74b (USD 272m)

*As of 29 August 2025

Two industrial-scale Cyclyx Circularity Centers in construction

The two USA-based centers have a combined capacity to produce approximately 150ktpa of custom feedstock for advanced recycling technologies.

On advanced recycling technology

Eight generations of technology development, a polystyrene waste recycling facility running on Styrenyx advanced recycling technology licensed to Toyo Styrene (a member of Denka Group), and 22 patents active in North America, the Middle East, Mexico and Asia.

Given the complexity of plastics, and the difficulty in sourcing post-use plastics,

feedstock availability is a enormous industry BOTTLENECK

With seven primary types of plastic and countless combinations of additives and contaminants, the plastic waste stream is incredibly complex and poses significant challenges for recyclers. Despite high demand for quality feedstock, many materials including films, foams, and multi-layer packaging are not widely accepted in easily accessible recycling services (curbside systems and drop-off facilities), leading to inconsistent recovery and limited supply. Adding to this challenge, each recycling technology requires a specific feedstock profile to operate efficiently.

Plastyx will address the feedstock supply shortage

New regulations and increased consumer environmental awareness are pressuring brands to increase their recycled content targets.

By 2030, advanced recycling supply capacity will lag announced required demand by 50%. This creates a significant challenge accessing appropriate feedstock to supply advanced recycling production facilities.

Plastyx is rising to the challenge by acting as a feedstock aggregator and pretreatment processor of European-sourced plastic waste

Source: ICIS, Plastyx Market Intelligence, McKinsey

New regulations and increased consumer environmental awareness are pressuring brands to increase their recycled content targets.

By 2030, advanced recycling supply capacity will lag announced required demand by 50%. This creates a significant challenge accessing appropriate feedstock to supply advanced recycling production facilities.

Plastyx is rising to the challenge by acting as a feedstock aggregator and pretreatment processor of European-sourced plastic waste

Source: ICIS, Plastyx Market Intelligence, McKinsey

Cyclyx offers tailored feedstock solutions for recycling technologies

Cyclyx stands alone in creating custom-formulated feedstock derived from post-use plastics for both advanced and mechanical recycling processes. Precision is made possible through proprietary technology encapsulating an extensive database cataloging the complexity of post-use plastics, chemical characterization and management, and state-of-the-art sortation and processing.

Cyclyx stands alone in creating custom-formulated feedstock derived from post-use plastics for both advanced and mechanical recycling processes. Precision is made possible through proprietary technology encapsulating an extensive database cataloging the complexity of post-use plastics, chemical characterization and management, and state-of-the-art sortation and processing.

Two Cyclyx Circularity Centers in the pipeline

The first center is under construction in Houston and is expected to start operations in 2025. The second is located in Dallas-Fort Worth, with an expected start of operations in 2026.

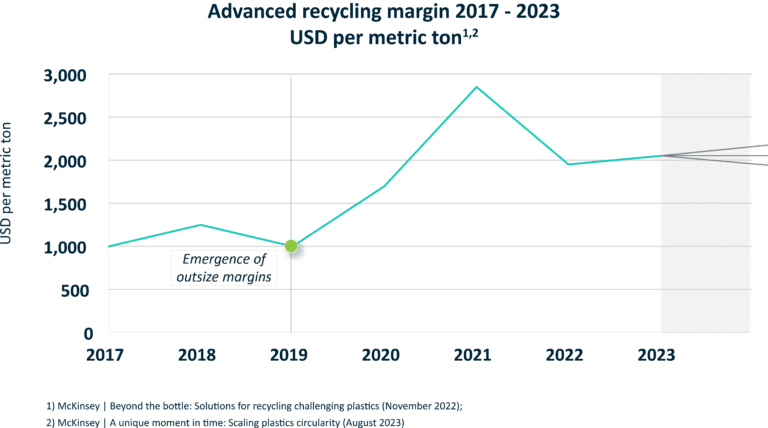

Strong growth in feedstock demand is supported by market conditions, presenting a unique investment opportunity in plastic recycling infrastructure.

There is substantial profit potential in the recycled plastics market

$2,000 per metric ton

Significant margins of up to $2,000 per metric ton available throughout the value chain

McKinsey: A unique moment in time: Scaling plastics circularity

$1,500 premium

Plastics derived from advanced recycling processes are commanding a premium, often selling for $1,500 or more per metric ton compared to traditional fossil fuel-based plastics.

McKinsey: Beyond the Bottle: Solutions for recycling challenging plastics

Premiums driven by a significant supply-demand imbalance

These high premiums are driven by a significant supply-demand imbalance. The availability of feedstock for advanced recycling lags behind announced capacity by as much as 60%.* Addressing this demand highlights the vital importance of Cyclyx Circularity Centers in fostering circularity and improving the handling of post-use plastic waste.

*Wood Mackenzie