OSLO, Norway – October 13, 2022 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, announced today that Louise Bryant will be joining the business as senior vice president of investor relations and sustainability, effective 1 November 2022. In her new role, Louise will be responsible for expanding the organization’s investor relations strategy and driving its sustainability initiatives.

Louise brings a wealth of investor relations experience to Agilyx, most notably serving as director of corporate affairs at Aggreko PLC, a FTSE 250 publicly traded company, where she built the investor relations program from the ground up and led the creation and development of the Group’s sustainability strategy during her eight-year tenure. Previous roles also include investor relations and communications at Costain Group and Thomas Cook Group, both publicly traded companies, and equity research analyst at Citi. Louise started her career with PwC where she qualified as a chartered accountant.

“We are pleased to welcome Louise to Agilyx,” stated Tim Stedman, CEO of Agilyx. “Her strong professional background working with investors and analysts, combined with her enthusiasm for taking on the global plastic crisis, will make Louise a vital member of the team as we work together to usher Agilyx into its next phase of growth.”

Louise will be based in the UK.

About Agilyx

Agilyx ASA is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds over 17 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com.

Contacts

Kate Ringier

VP, Communications & Government Affairs

+ 41 43 883 0396

kate.ringier@agilyx.com

Oslo, [September 16, 2022] – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, today has its first day of trading on the main board of Euronext Oslo Børs, following an uplisting from Euronext Growth Oslo. The Agilyx shares trade under the ticker “AGLX” on Oslo Børs and on the US marketplace OTCQX under the ticker “AGXXF”.

“The uplisting is an important milestone for Agilyx, almost exactly two years since we first went public on Euronext Growth in Oslo. Taking the step up to a regulated market is not only a confirmation of the quality of our business model, technology, and internal processes, it is also the result of successful operational and commercial development. Following years of relentless focus on business development and fostering of technology partnerships we now step into a phase of rapid growth in activity and revenue. Our pipeline of projects is growing fast, and we see a clear path towards our revenue goal of USD 200-300 million by 2025/2026,” said CEO of Agilyx Tim Stedman.

A leader in chemical recycling, Agilyx technology gives post-use plastic a new, circular life by converting this valuable material back into its original building blocks for reuse. By enabling plastic circularity on a global and commercial scale, Agilyx plays a vital role in accelerating the shift to a low-carbon economy.

With Agilyx’s chemical recycling technology and intelligent feedstock management system via Cyclyx, mixed plastic waste can be converted to new virgin equivalent plastics – creating the opportunity for true circularity.

Contact:

Kate Ringier VP, Communications & Government Affairs

+ 41 43 883 0396

kate.ringier@agilyx.com

About Agilyx

Agilyx is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds over 17 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products.

Learn more at www.agilyx.com.

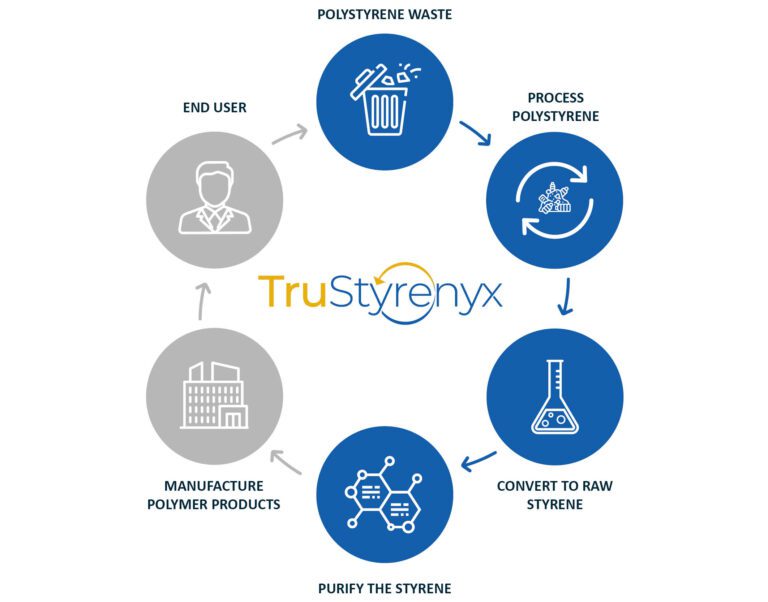

TruStyrenyx™: All-in-one technology platform for the advanced recycling of polystyrene

Download Brochure

A first of its kind solution

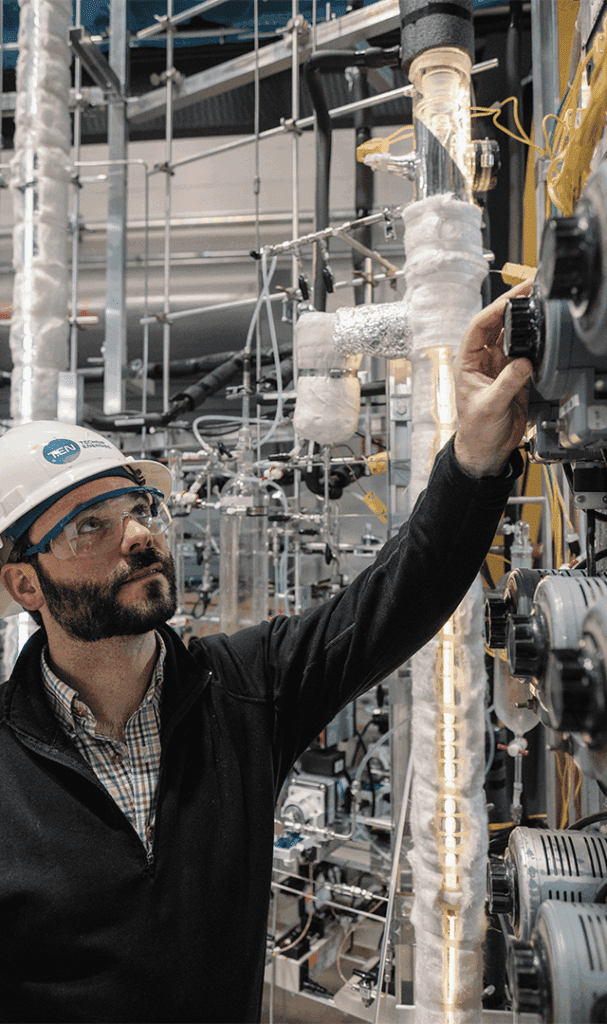

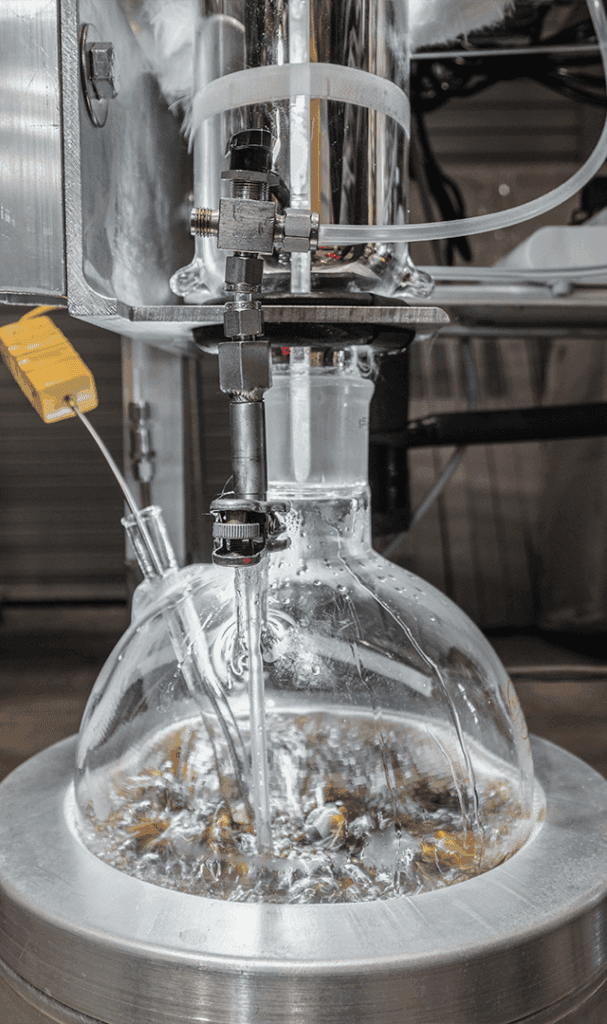

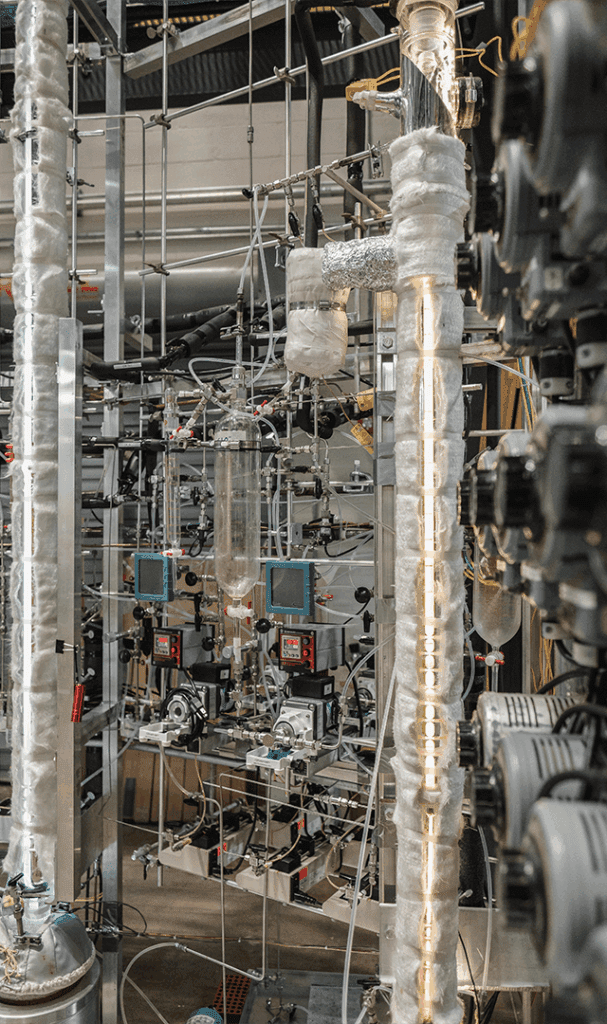

The solution deploys Styrenyx, Agilyx’s depolymerization technology via pyrolysis with Technip Energies’ purification expertise, yielding a recycled styrene monomer of exceptionally high purity.

What makes TruStyrenyx unique?

Combine Styrenyx™ depolymerization and Technip Energies’ purification technologies

Convert waste polymer to highly purified styrene monomer

Remove flame retardants

Learn more about the only fully integrated advanced recycling solution for polystyrene waste on the market today

Download BrochurePORTSMOUTH, New Hampshire, USA, August 10, 2022 – Cyclyx International, a consortium-based post-use plastic innovation company with a mission to increase the recyclability of plastic from 10% to 90%, has announced that Styropek, the largest expandable styrene (EPS) manufacturer in America and a subsidiary of Alpek, has joined the consortium.

Alpek has committed to grow its long-term usage and sustainable applications for EPS, work on biodegradable alternatives, and increase recycling content in select products to at least 30% by 2030. Having more feedstock available will significantly support Styropek’s EPS projected recycling capacity to achieve its circularity target. Through its expertise in understanding the chemical composition of waste plastic, Cyclyx can deliver ISCC PLUS certified custom feedstock batches with the necessary chemical and physical properties to ensure its recyclability.

“We are pleased to have joined Cyclyx as it will allow us to gain valuable recycled feedstock,” stated Andreas Plettner, CEO of Styropek. “We are confident that Alpek’s target aligns well with Cyclyx’s mission to drive up recycling rates of plastics.”

Styropek’s EPS production is primarily used for long-term industries such as construction due to its thermal insulation properties which allow it to reduce the carbon footprint for homes and buildings. However, for its short-term usage products, the Company continues to establish its role as a leading recycler, now through growth in Expandable Styrenics recycling.

“We are excited to welcome Styropek to Cyclyx,” stated Joe Vaillancourt, CEO of Cyclyx. “Their circularity goals and commitment to developing sustainable applications for EPS align well with our mission to increase the recyclability of plastic from 10% to 90%.”

About Cyclyx International, LLC.

Cyclyx International, LLC. (“Cyclyx”) is a post-use plastic innovation company working with industry participants to develop innovative recycling solutions for all types of post-use plastics. The company’s mission is to increase the recyclability of plastics from 10% to 90% by using Cyclyx’s expertise in understanding the chemical composition of post-use plastic in collaboration with industry partners to create a new, innovative supply chain. Cyclyx was founded by Agilyx Corporation (“Agilyx”), a leader in advanced chemical recycling, together with ExxonMobil Chemical Company, one of the largest chemical companies in the world. Cyclyx has been formed to be a consortium-based entity and since its founding there have been a growing number of companies joining its membership. For more information, visit us at www.cyclyx.com.

About Alpek

Alpek is a leading petrochemical company operating two business segments: “Polyester” (PTA, PET, rPET, and polyester fibers), and “Plastics & Chemicals” (polypropylene, expandable styrenics, and other specialty & industrial chemicals). Alpek is a leading producer of PTA, PET resin and PET sheet worldwide, one of the largest rPET producers in the Americas, the third largest expandable polystyrene manufacturer worldwide, and the only producer of polypropylene in Mexico. In 2021, Alpek reported revenues of U.S. $7.7 billion and Comparable EBITDA of U.S. $962 million. The Company operates 35 plants across the United States, Mexico, Canada, Brazil, Argentina, Chile, Oman, Saudi Arabia, and the United Kingdom, and employs over 7,000 people. Alpek is a publicly traded company listed on the Mexican Stock Exchange.

Media Contact

Melanie Burger

Director, Corporate Communications

mburger@cyclyx.com

OSLO, Norway – July 25, 2022 – Agilyx (Euronext Growth Oslo: AGLX.OL; OTCQX: AGXXF), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, announced today the appointment of Stephen Hamlet to vice president of human resources, effective immediately. Mr. Hamlet joins Agilyx as a people-centric leader who will build and unite the company’s rapidly-growing global team.

With over 20 years of diverse HR leadership and hands-on HR operations experience, Stephen possesses a strong background in developing and leading human resources in manufacturing, technology, and many other industries. In his new role, Mr. Hamlet will lead all HR functions for Agilyx including employee engagement, training and development, diversity and inclusion initiatives, recruitment and day-to-day workforce operations. He holds an MBA with a focus in Human Resources Management from Louisiana State University – Shreveport.

“We are pleased to welcome Stephen to the team,” stated Tim Stedman, CEO of Agilyx. “His entrepreneurial mindset and broad background across industries, particularly in the technology and waste to energy industries, provides him a ready familiarity with what we are trying to accomplish at Agilyx. Stephen brings the unique experience and dedication we need to build a world-class business culture centered around our people.”

About Agilyx

Agilyx is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds over 17 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com.

Contacts

Kate Ringier

VP, Communications & Government Affairs

+ 41 43 883 0396

kate.ringier@agilyx.com

YewMaker, the executive lead of the Sustainable Medicines Partnership (SMP), is announcing that Agilyx has joined as a Founding Collaborator. The SMP is a not-for-profit private-public collaboration executing projects to make the use of medicines more sustainable and less wasteful.

Agilyx (Euronext Growth (Oslo): “AGLX”) is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products.

In its collaboration with the SMP, Agilyx will have an initial focus on enhancing medicines packaging sustainability. Roughly one trillion medicine packets are thrown away each year, destined for landfill or incineration even though most could be recycled. Eliminating the single use of these plastics is a priority for the SMP.

“Sustainable Medicines Partnership has an exemplary goal to make medicines more sustainable and equitable. Agilyx is extremely proud to join SMP in its work to reduce waste in medicines packaging,”. “There is a perception out there that packaging like blister packs can’t be recycled, but that is not the case. Our proven technology can create a more sustainable solution for this high-grade medical packaging.” – Tim Stedman, CEO of Agilyx

Agilyx will work with SMP to develop tested, data-driven, scalable solutions to address the factors that have previously made these materials hard to recycle such as the chemical complexity of the plastics involved and the logistical difficulties with collection, sorting and disposal in a highly siloed industry.

“Packaging plays an essential role in ensuring the quality and safety of medicines. Developing circular solutions to reduce single use of plastics in medicines packaging is a key focus of the SMP. We are delighted Agilyx, who are leading innovators in recycling complex plastics, will be working with us.”- Nazneen Rahman, YewMaker CEO, SMP Director.

Contacts:

YewMaker: comms@yewmaker.com

Agilyx: Kate Ringier kate.ringier@agilyx.com

About the Sustainable Medicines Partnership

The SMP is a not-for-profit, private-public, multi-stakeholder collaboration. Through executing priority actions, the Sustainable Medicines Partnership aims to stop the avoidable waste of medicines and medicines packaging – reducing healthcare emissions and increasing health equity globally. Learn more at www.yewmaker.com/smp

About YewMaker

YewMaker builds science-based, scalable, concepts and solutions that make healthcare more sustainable. YewMaker is the initiator and executive lead of the Sustainable Medicines Partnership. Learn more at www.yewmaker.com

About Agilyx

Agilyx is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds over 17 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com.

Oslo, Norway – February 21, 2022 – Agilyx (Euronext Growth Oslo: AGLX.OL; OTCQX: AGXXF), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, announced today the appointment of Jonathan Tyler as senior vice president of corporate development to help drive the company’s strategic planning process and investor relations strategy.

Mr. Tyler comes to Agilyx with over 25 years of experience in investment banking with a longstanding specialization across the chemical industry with related work in cleantech and sustainability. Tyler has held leadership positions with Houlihan Lokey, Bear Stearns (now JP Morgan), Goldman Sachs and Climate KIC. Early in his career he was a top ranked research analyst, including heading European chemical research for Goldman Sachs. He has worked on many of the most complex M&A and financial restructuring projects across the global chemical industry, and also numerous IPOs/listings. Most recently he served as managing director at Perella Weinberg Partners.

“We are excited to welcome Jonathan to Agilyx with his wealth of experience in strategic decision making and investor relations,” stated Tim Stedman, CEO of Agilyx. “Jonathan’s strong professional background will be vital in developing the strategic relationships needed to usher Agilyx into its next phase of growth.”

Mr. Tyler will be based at the company’s European hub, located just outside of Zurich, Switzerland.

Contacts

Kate Ringier

VP, Communications & Government Affairs

+ 41 43 883 0396

kate.ringier@agilyx.com

About Agilyx

Agilyx is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds over 17 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com.

Virgin Group and chemical conversion technology company Agilyx have announced they are forming a strategic partnership in order to research and develop lower-carbon fuel facilities to help address plastic pollution and the global transition to net-zero

Virgin Group and Agilyx aim to reuse plastic waste to produce synthetic crude oil that will then be refined into a lower carbon fuel. Plastic waste that otherwise would be un-recycled will be diverted from landfill and will help broaden options in the market for lower carbon fuels from the limited range available today. Virgin Group wants to provide lower carbon fuel solutions to the global-market and expects Virgin Atlantic and other Virgin companies to be early adopters, as part of the Group’s transitional plans of achieving net zero by 2050.

Virgin Group intends to work with Agilyx – whom it has been an investor in for many years – on the development of the production facilities based on its unique conversion technology. Cyclyx, an innovative feedstock company that is majority owned by Agilyx, will source the plastic waste used for the fuel in the first facility.

The first waste-to-fuel location is planned to be in the US, with an aspiration to roll-out similar plants in other countries, including the UK.

Agilyx’s proprietary technology is able to break down plastic waste through a pyrolysis process. Pyrolysis converts mixed waste plastic into a synthetic crude oil which, once further refined, can be used as a lower carbon fuel.

Josh Bayliss, CEO of the Virgin Group, says: “Innovation and entrepreneurship are important tools to address the climate crisis. Virgin and other companies have an important role to play in meeting those challenges, which is exactly why we are forming this strategic partnership with Agilyx. The creation of lower carbon fuel is an important step in the journey towards net zero. We are very pleased to be adding this project to the range of investments we continue to make aimed at addressing these issues.”

Tim Stedman, CEO of Agilyx, says: “We are pleased to be partnering with the Virgin Group to enable a technology solution for lower carbon fuels as it transitions on its journey to net zero. This platform is unique as it will be used for lower carbon fuels and has the future opportunity for the production of circular plastics. We view plastic waste as a valuable above ground resource that is not widely tapped into. Through our technology, we aim to unlock the value of plastic waste that otherwise may have been destined for landfill or incineration.”

Shai Weiss, CEO of Virgin Atlantic, says: “In this decade, Sustainable Aviation Fuel is the key solution for decarbonisation of the aviation sector but we have a long way to go. Clearing the skies for tomorrow requires radical collaboration across innovators, producers, investors and airlines. We are delighted that Virgin Group and Agilyx are leading the charge to pilot new pathways in lower carbon fuels and we look forward to working closely with them to achieve our 10% SAF target by 2030.”

-ends-

For further information:

Charlotte Sjoberg

Communications Director, UK, Virgin

+44 7766 240821

charlotte.sjoberg@virgin.com

Kate Ringier

VP, Communications & Government Affairs, Agilyx

+ 41 43 883 0396

kate.ringier@agilyx.com

Virgin Atlantic

For further press information about Virgin Atlantic, please contact the Virgin Atlantic press office on press.office@fly.virgin.com or call 01293 747373.

Ryan Kisiel

Head of Sustain, Maitland /AMO

+44 (0) 207 379 5151

ryan.kisiel@maitland.co.uk

Notes to editors

Virgin companies which are expected to be early adopters of the lower carbon fuel include Virgin Atlantic, Virgin Australia and Virgin Orbit. Virgin Voyages will also explore how the lower carbon fuel could advance its net zero goals.

About Virgin

The Virgin Group is a leading international investment group and one of the world’s most recognised and respected brands. Created in 1970 with the birth of Virgin Records, the Virgin Group has gone on to invest in, incubate, and grow a number of successful businesses in the private and public markets. The Virgin Group has expanded into many sectors since its inception, driven by Sir Richard’s ambition to create the world’s most irresistible brand. These sectors include travel & leisure, financial services, health & wellness, technology & internet-enabled, music & entertainment, media & mobile, space, and renewable energy. Avoiding the impacts of climate change is a key priority for the Virgin branded businesses and we believe that all Virgin branded companies should achieve net zero emissions by 2050 or sooner, further details on this will be published in the Virgin Group sustainability report later this year. Find out more at www.virgin.com.

About Agilyx

Agilyx is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds more than 17 patents. Agilyx conversion technology utilises pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com.

About Virgin Atlantic

Virgin Atlantic was founded by entrepreneur Sir Richard Branson in 1984, with innovation and amazing customer service at its core. In 2021, Virgin Atlantic was voted Britain’s only Global Five Star Airline by APEX for the fifth year running in the Official Airline Ratings. Headquartered in London, it employs 6,500 people worldwide, flying customers to 27 destinations across four continents. Alongside shareholder and Joint Venture partner Delta Air Lines, Virgin Atlantic operates a leading transatlantic network, with onward connections to more than 200 cities around the world. On 3 February 2020, Air France-KLM, Delta Air Lines and Virgin Atlantic launched an expanded Joint Venture, offering a comprehensive route network, convenient flight schedules, competitive fares and reciprocal frequent flyer benefits, including the ability to earn and redeem points / miles across all carriers.

Sustainability remains central to Virgin Atlantic, having taken an industry leadership position through its long-standing support for SAF commercialisation and fleet transformation programme. Since September 2019, the airline has welcomed eight new Airbus A350-1000 with a further A350-100 and three A339s entering the fleet in 2021. By the end of 2022 the average fleet age will be just over six years, driving a fuel efficiency (CO2 /RTK) improvement of 30% compared with 2007. For more information visit www.virginatlantic.com or via Facebook, Twitter and Instagram @virginatlantic.

PORTLAND, Oregon, USA – January 11, 2022 – Agilyx, (Euronext Growth Oslo: AGLX.OL; OTCQX: AGXXF) a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products and Toyo Styrene Co., LTD (“Toyo Styrene”), an affiliate of Denka Company Limited, Nippon Steel Chemical & Material Co., Ltd. and Daicel Co., Ltd., announced today they are entering into the construction phase of a 10 ton per day chemical recycling facility in Japan, enabled by Agilyx depolymerization technology.

The recycling plant will convert post-use polystyrene into a styrene monomer that will be purified using Toyo Styrene’s proprietary purification process. Styrene monomer produced from this process can then be converted back into high value polystyrene products which bear a significantly lower carbon footprint than similar products made with virgin monomer.

“As the first step toward the circular economy, we will construct a chemical recycling plant for this project, collect post-industrial materials for the time being, and start a chemical recycling business.” said Sanshiro Matsushita, President of Toyo Styrene. “Furthermore, in order to build a carbon free society through chemical recycling in Japan, we are also planning to participate in a platform that integrates citizens, businesses, and local government, which is being undertaken by Ichihara City, Chiba Prefecture.”

“The decision to move into the final stages of this project is a big accomplishment for the members of Agilyx and Toyo Styrene who have worked tirelessly to bring us to this point,” stated Tim Stedman, CEO of Agilyx. “We are very proud of their efforts and excited for the opportunity to bring our proven advanced recycling technology into the Asian markets to help improve the availability of recycled plastic content and increase global plastic recycling through circular pathways.”

Contacts

Kate Ringier

VP, Communications & Government Affairs

+ 41 43 883 0396

kate.ringier@agilyx.com

Toyo Styrene

Hiroshi Higuchi, Executive Officer, the office manager, environmental measures promotion office, Toyo Styrene Co.,Ltd.

+81-3-3519-5602

h-higuchi@toyo-st.co.jp

About Agilyx

Agilyx is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a molecular recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale closed loop plastic-to-plastic chemical recycling facility and holds over 17 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com.

About Toyo Styrene

Toyo Styrene was established in April 1999 as a company of consolidated polystyrene business carved out from Denki Kagaku Kogyo Kabushiki Kaisha (Current: Denka Co., Ltd.), Nippon Steel Chemical Co., Ltd. (Current:NIPPON STEEL Chemical & Material Co., Ltd.),and Daicel Chemical Co.(Current:Daicel Corporation). Since then, Toyo Styrene has been developing constantly the new high performance grade for answering the needs of customers such asEX7, HMT1, GA, Eneryts and FR-PS as well. For more information, follow us on social media and visit us at www.toyo-st.co.jp.

Full production scale trial successfully proves technology for depolymerizing acrylic

TEESSIDE, England and OSLO, Norway, December 8, 2021 – Mitsubishi Chemical Methacrylates (MCM) and partner, Agilyx Corporation (OSE: AGLX), a wholly owned subsidiary of Agilyx AS (Euronext Growth (Oslo): “AGLX”) and a pioneer in the chemical recycling of post-use plastics, announced today the successful results of a full-scale production trial for polymethyl methacrylate (PMMA; commonly called acrylic) depolymerization at Agilyx’s facility in Tigard, Oregon.

The full-scale trial, conducted in August 2021, returned results consistent with the successful results of a laboratory-scale trial conducted in 2020. A mixed feedstock included both cast and extruded PMMA sheet, and the effects of different temperature settings were analysed to find the optimal conditions for PMMA pyrolysis.

Following the successful plant trial, experts from MCM and Agilyx met to build an action plan that sets out the required next steps.

“The results at full production scale are very encouraging,” said David Smith, circular economy programme lead, Mitsubishi Chemical Methacrylates. “The teams at both MCM and Agilyx worked very well together, and all parties are excited at the prospect of building a new PMMA depolymerization plant using Agilyx technology.”

“The results of our PMMA trials in Tigard have been very positive,” stated Carsten Larsen, CCO of Agilyx. “We’ve proven that Agilyx technology is capable of turning PMMA back into its original monomer, MMA, creating a truly circular material. We’re excited to continue our collaboration with Mitsubishi Chemical Methacrylates.”

The crude MMA produced during the plant trial is currently being distilled at MCM’s pilot plant in Wilton, England and will be used both for internal product development and to validate the purification solution that will be used in this process.

For further information, contact:

Scott Neal – Communications Specialist, Mitsubishi Chemical Methacrylates

Tel: +44 (0)1642 735066

scott.neal@m-chem.com

David Smith – Circular Economy Programme Lead, Mitsubishi Chemical Methacrylates

Tel: +44 (0)7885 239742

david.smith@m-chem.com

Kate Ringier – VP, Communications and Government Affairs, Agilyx

Tel: + 41 43 883 0396

kate.ringier@agilyx.com

About Mitsubishi Chemical Methacrylates

Mitsubishi Chemical Methacrylates (MCM) is the global Methacrylates Division of Mitsubishi Chemical and the world’s largest producer of methyl-methacrylate (MMA). With manufacturing sites, sales offices and distribution networks throughout Asia, the Americas and Europe, MCM creates products that improve the quality of life around the world, every single day. Learn more at www.mcc-methacrylates.com.

About Agilyx Corporation

Agilyx (AGLX) is an early leader in the advanced recycling of difficult-to-recycle post-use plastics. With Agilyx’s chemical recycling technology, mixed plastic waste or streams of discrete post-use plastics, such as polystyrene, can be converted to new virgin-equivalent plastics, as well as chemical products and fuels – creating the opportunity for true circularity. The company has not only developed these first-to-market products but has also developed a feedstock management company, Cyclyx International, LLC, and is partnering with a range of waste service providers, municipalities, petrochemical, and brand and retail companies to develop closed-loop recycling solutions for mixed waste plastics. www.agilyx.com.

Circular recycling company, Regenyx, confirmed today that it has transitioned to 100% renewable energy at its facility in Tigard, Oregon. The company is a joint venture between Agilyx Corporation (AGLX), a wholly owned subsidiary of Agilyx AS (Euronext Growth (Oslo): “AGLX”) and pioneer in the advanced recycling of post-use plastics, and AmSty, the largest polystyrene producer in the Americas. Joining together to form Regenyx in 2019, these companies are considered frontrunners in circular recycling for polystyrene and aim to lead future companies in choosing renewable energy.

Through enrollment in the Green Future Enterprise program with Portland General Electric (PGE), Regenyx will receive 100% of its electricity from wind sources. Using solely renewable energy sources supports a transition to a low-carbon economy, which is in line with Agilyx sustainability goals to mitigate climate-related impacts of its operations and disclosing the environmental footprint and energy efficiency of its circular recycling processes.

“Agilyx is using chemical recycling technology to help solve the problem of plastic waste in an effort to create a more sustainable, circular economy for plastics,” said Tim Stedman, CEO of Agilyx. “Using electricity derived from non-renewable resources to power that technology would be counter-intuitive. That’s why we are so pleased to announce that all of the electricity in Tigard will now come from renewable wind energy.”

Vice President of Polymers and Sustainability at AmSty, Tim Barnette, said, “AmSty and Agilyx are working diligently to make circular recycling as efficient and carbon-neutral as possible. We are optimistic that the move to wind-powered electricity will put us farther down that path and we’re grateful to have this source available.”

Contacts

Kate Ringier

VP, Communications & Government Affairs

+ 41 43 883 0396

kate.ringier@agilyx.com

Josh Want

Communications Manager

AmSty

Phone: +1 844-512-1212

Website: www.amsty.com

About Agilyx

Agilyx (AGLX) is an early leader in the advanced recycling of difficult-to-recycle post-use plastics. With Agilyx’s chemical recycling technology, mixed plastic waste or streams of discrete post-use plastics, such as polystyrene, can be converted to new virgin-equivalent plastics, as well as chemical products and fuels – creating the opportunity for true circularity. The company has not only developed these first-to-market products but has also developed a feedstock management company, Cyclyx International, LLC, and is partnering with a range of waste service providers, municipalities, petrochemical, and brand and retail companies to develop closed-loop recycling solutions for mixed waste plastics. www.agilyx.com.

About AmSty

AmSty is a leading integrated producer of polystyrene and styrene monomer, offering solutions and services to customers in a variety of global markets. AmSty is a member of the American Chemistry

Council and its Responsible Care initiative, and is headquartered in The Woodlands, Texas. AmSty is a joint venture equally owned by Chevron Phillips Chemical Company LP and Trinseo LLC.