OSLO, Norway – March 20th, 2025 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”) announces that production of styrene via Styrenyx, its proprietary polystyrene recycling technology, significantly reduces carbon equivalent emissions compared to producing styrene from fossil resources.

To better assess the carbon footprint of our advanced recycling, post-consumer waste circular styrene production, Agilyx commissioned Sphera Solutions, Inc. to perform a cradle-to-gate product carbon footprint (PCF) and compare results to conventional production of styrene from fossil resources. Results indicate that Agilyx’s process lowers carbon equivalent emissions by 38% using average grid electricity and 86% using wind electricity as compared to conventional styrene made from fossil resources. The study has been conducted according to the requirements of the International Organization for Standardization (ISO) 14067:2019-02 (ISO, 2019) and is currently undergoing independent critical review by 3rd party expert, in accordance with ISO/TS 14071:2014 (ISO, 2024). The expert review is expected to be complete in Q2 2025.

For context, these results indicate that an Agilyx facility producing 18,000 metric tons of styrene annually and powered by grid electricity could reduce the equivalent of ~15,000 metric tons of CO2 emissions compared to conventional styrene. This is equivalent to removing ~3,500 gasoline cars off the road for a year (~6.4 million litres /1.7 million gallons of gasoline) or the amount of CO2 sequestered by 245,000 tree seedlings over a decade (US EPA, 2024). Global production of styrene is projected to reach 16.75 million tonnes by 2026. If 10% of this volume were produced using Styrenyx, it would be the equivalent to removing 325,000 gasoline cars from the road annually.

“We are extremely encouraged by these results and remain committed to further reducing our carbon footprint” said Chris Faulkner, Chief Technology Officer of Agilyx. “By leveraging sustainable energy sources and innovative recycling technologies, we will reduce global carbon emissions and help solve the plastic waste challenge.”

About Agilyx

Agilyx ASA is at the forefront of plastic waste recycling, enabling the conversion of challenging post-use plastics into high-value, virgin-equivalent products. Recognizing that availability of high-quality custom feedstock is critical for scaling recycling processes, Agilyx, through its Cyclyx joint venture, provides tailored feedstock solutions to global plastic producers. In addition, Agilyx leverages its Styrenyx technology platform and T.EN’s purification technology to market TruStyrenyx – a full polymer-to-monomer advanced recycling solution for polystyrene. By advancing from a linear “make-take-waste” model to a sustainable circular economy, Agilyx supports the transition to a low-carbon future. Our adaptable approach ensures bespoke solutions, leveraging extensive IP and feedstock expertise to meet diverse customer needs. For more information, visit Agilyx’s corporate website www.agilyx.com

For investor inquiries contact: communications@agilyx.com

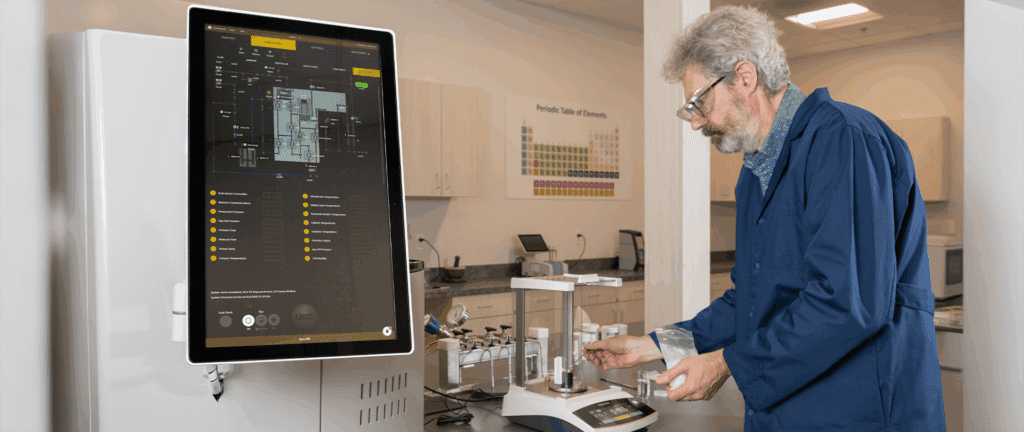

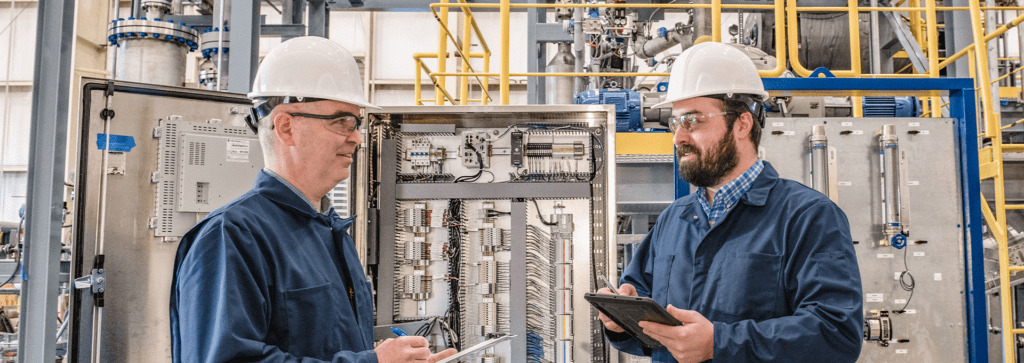

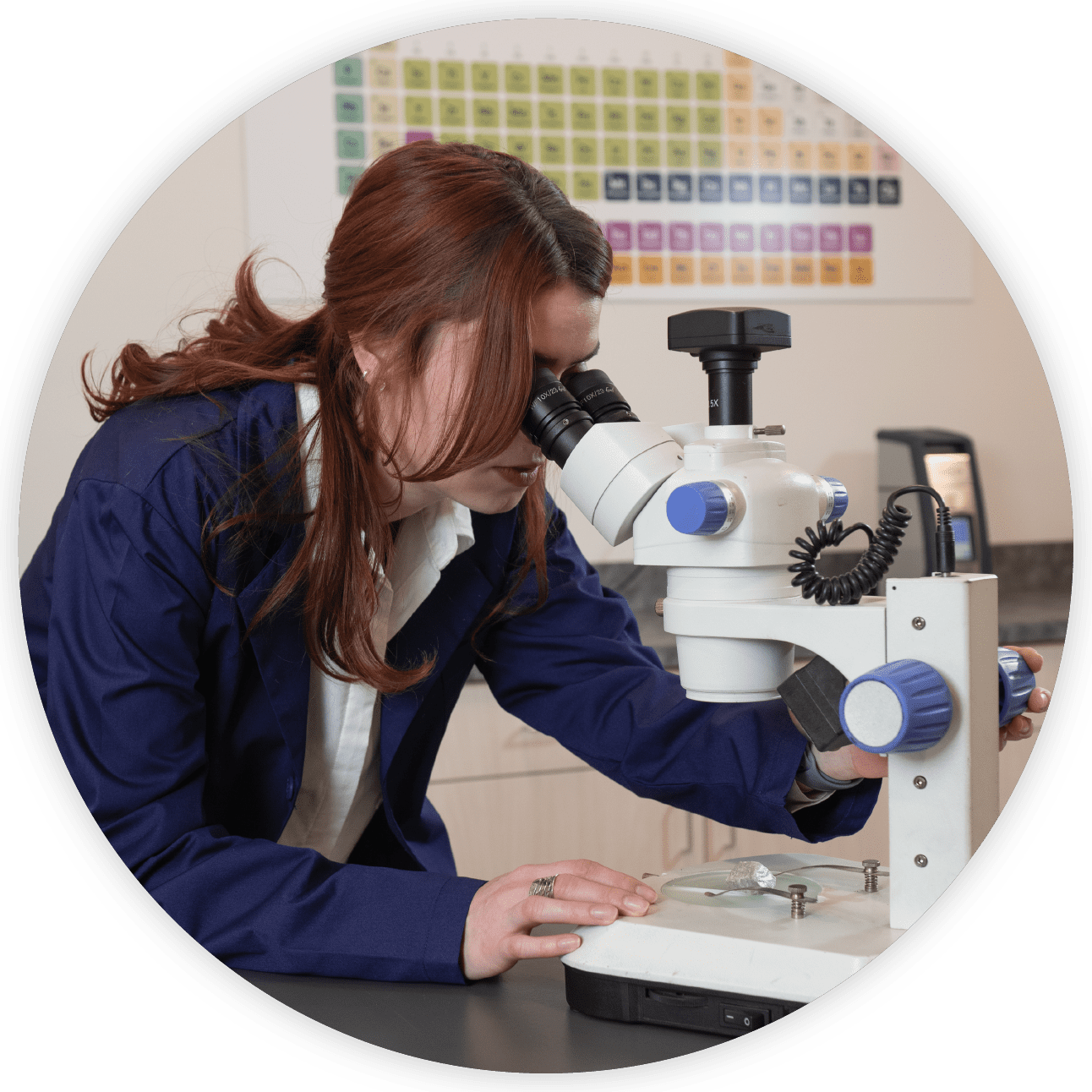

Agilyx Research Center – The ARC

Agilyx brings more than 20 years of expertise in analyzing the chemical complexity of plastic waste. This knowledge enables us to transform hard-to-recycle plastics into valuable resources instead of becoming waste.

Services we provide

The ARC provides a range of services including characterization and identification of plastic streams that can be turned into feedstock sources matched to advanced recycling processes. Projects range from small-scale lab, through pilot plan, to full-scale identification and design of commercial facilities.

Expertise in chemical characterization of plastic waste

Using our extensive polymer and mixed polymer expertise (including co-polymers, binders, multi-layers), plastic sources can be matched to provide rapid turnaround of suggested pathways. Follow-up with physical characterization, pilot-scale processing, pre and post-processing treatment and sample generation provide data that can be used as design input for full-scale process design projects.

Helping our customers recycle plastic waste

Do you have waste or a hard-to-recycle plastic?

Do you want to investigate the potential pathways to turning that material into useful products via advanced recycling?

Do you want to do a feasibility study for recycling of large volumes of material?

We can create a custom project plan to match your requirements and budget from “Can I recycle this material?” to “I want to build a large commercial facility” and all points in-between.

Products and Services

Discover our solutions for

plastic waste

Products & Services

Plastic waste solutions

From feedstock management to advanced recycling technology, Agilyx helps solve the problem of plastic waste by investing in solutions that help shift our world from a linear, “make-take-waste” economy, to a more sustainable “retrieve-restore-recycle” economy, aiding the transition to a lower-carbon future.

Our Solutions

Cyclyx

A pioneer and key enabler for the recycling industry, converting post-use plastic waste into high-quality feedstock

Styrenyx

Agilyx’s proprietary advanced recycling technology for polystyrene waste, available for licensing and equipment sourcing

TruStyrenyx

Polystyrene waste to styrene monomer platform combining Styrenyx depolymerization and Technip Energies’ purification technologies

Our Services

Agilyx’s technical services leverage decades of expertise in chemical technology to deliver innovative, scalable solutions for plastic waste. From process design to operator training, our team provides the technical knowledge and support needed to optimize recycling systems and drive circularity.

Agilyx Research Center Services

The Agilyx Research Center (the ARC) provides a range of services to characterize and identify plastic streams that could be turned into feedstock sources and match those to advanced recycling processes. Projects can range from small-scale lab, through pilot plant to full-scale identification and design of commercial facilities.

Rapid matching using our extensive

feed-to-product expertise

Bench & pilot-scale advanced depolymerization

Feed, product and by-product physical and chemical analysis

Feed characterization services

Generation of multi-liter quantities of products for evaluation purposes

Packaged Feasibility Studies

Detailed feedstock specification definition

Providing Experimental Data Inputs for scale-up & commercial designs

Pre- and post-process treatment

Technical Collaborations

Includes R&D design and technical services – from a process design package (PDP) to detailed design, integration, permitting support, and other project support needs

Equipment Supply

Agilyx will source, sell and supply all necessary equipment for our depolymerization process, including our proprietary pyrolysis reactor and oil conditioning system

Commissioning Services

Services to commission the supplied core equipment, provide integration support,

and basic operational training

Operator Training Program

We offer a comprehensive “train-the-trainer” program to ensure customers produce the maximum value from the process

With decades of expertise in plastics and advanced recycling, Agilyx has developed a deep understanding of the chemical complexity of plastic waste. Our knowledge drives innovation, enabling scalable solutions that transform plastic waste into valuable resources.

Dr. Chris Faulkner, Chief Techology Officer

To solve the plastic recycling problem, collaboration is key Across the value chain, Agilyx excels as a collaborator in solving the plastic waste problem. We understand that recycling is never a one-size-fits-all solution. Our flexible approach allows us to tailor solutions for our customers’ specific needs.

Make an inquiry

Across the value chain, Agilyx excels as a collaborator in solving the plastic waste problem. We understand that recycling is never a one-size-fits-all solution. Our flexible approach allows us to tailor solutions for our customers’ specific needs.

Why invest in Agilyx?

Agilyx is a publicly traded, technology-agnostic leader in the plastic recycling sector, trusted by blue-chip partners. We present a strong, diversified-exposure investment opportunity in the advanced recycling industry with funded projects that promote future growth and present a clear path to profitability.

Agilyx at a glance

A publicly traded company

Listed on the Oslo Stock Exchange (OSE) since September 2022, with a market capitalization* of NOK 2.74b (USD 272m)

*As of 29 August 2025

Two industrial-scale Cyclyx Circularity Centers in construction

The two USA-based centers have a combined capacity to produce approximately 150ktpa of custom feedstock for advanced recycling technologies.

On advanced recycling technology

Eight generations of technology development, a polystyrene waste recycling facility running on Styrenyx advanced recycling technology licensed to Toyo Styrene (a member of Denka Group), and 22 patents active in North America, the Middle East, Mexico and Asia.

Given the complexity of plastics, and the difficulty in sourcing post-use plastics,

feedstock availability is a enormous industry BOTTLENECK

With seven primary types of plastic and countless combinations of additives and contaminants, the plastic waste stream is incredibly complex and poses significant challenges for recyclers. Despite high demand for quality feedstock, many materials including films, foams, and multi-layer packaging are not widely accepted in easily accessible recycling services (curbside systems and drop-off facilities), leading to inconsistent recovery and limited supply. Adding to this challenge, each recycling technology requires a specific feedstock profile to operate efficiently.

Plastyx will address the feedstock supply shortage

New regulations and increased consumer environmental awareness are pressuring brands to increase their recycled content targets.

By 2030, advanced recycling supply capacity will lag announced required demand by 50%. This creates a significant challenge accessing appropriate feedstock to supply advanced recycling production facilities.

Plastyx is rising to the challenge by acting as a feedstock aggregator and pretreatment processor of European-sourced plastic waste

Source: ICIS, Plastyx Market Intelligence, McKinsey

New regulations and increased consumer environmental awareness are pressuring brands to increase their recycled content targets.

By 2030, advanced recycling supply capacity will lag announced required demand by 50%. This creates a significant challenge accessing appropriate feedstock to supply advanced recycling production facilities.

Plastyx is rising to the challenge by acting as a feedstock aggregator and pretreatment processor of European-sourced plastic waste

Source: ICIS, Plastyx Market Intelligence, McKinsey

Cyclyx offers tailored feedstock solutions for recycling technologies

Cyclyx stands alone in creating custom-formulated feedstock derived from post-use plastics for both advanced and mechanical recycling processes. Precision is made possible through proprietary technology encapsulating an extensive database cataloging the complexity of post-use plastics, chemical characterization and management, and state-of-the-art sortation and processing.

Cyclyx stands alone in creating custom-formulated feedstock derived from post-use plastics for both advanced and mechanical recycling processes. Precision is made possible through proprietary technology encapsulating an extensive database cataloging the complexity of post-use plastics, chemical characterization and management, and state-of-the-art sortation and processing.

Two Cyclyx Circularity Centers in the pipeline

The first center is under construction in Houston and is expected to start operations in 2025. The second is located in Dallas-Fort Worth, with an expected start of operations in 2026.

Strong growth in feedstock demand is supported by market conditions, presenting a unique investment opportunity in plastic recycling infrastructure.

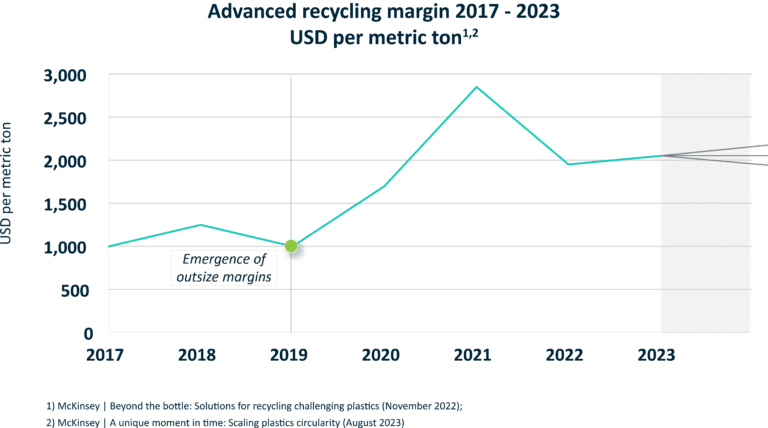

There is substantial profit potential in the recycled plastics market

$2,000 per metric ton

Significant margins of up to $2,000 per metric ton available throughout the value chain

McKinsey: A unique moment in time: Scaling plastics circularity

$1,500 premium

Plastics derived from advanced recycling processes are commanding a premium, often selling for $1,500 or more per metric ton compared to traditional fossil fuel-based plastics.

McKinsey: Beyond the Bottle: Solutions for recycling challenging plastics

Premiums driven by a significant supply-demand imbalance

These high premiums are driven by a significant supply-demand imbalance. The availability of feedstock for advanced recycling lags behind announced capacity by as much as 60%.* Addressing this demand highlights the vital importance of Cyclyx Circularity Centers in fostering circularity and improving the handling of post-use plastic waste.

*Wood Mackenzie

Agilyx is changing the way the world recycles

Agilyx is dedicated to solving the problem of plastic waste by investing in solutions across the value chain, from feedstock supply derived from post-use plastics to the recycling industry, to innovative advanced recycling technology.

Contact us

Increasing the recyclability of post-use plastics

Offering solutions for plastic waste through advanced recycling technology and feedstock processing capabilities

Solving the plastic waste crisis will require paradigm-breaking systems and technology. At Agilyx, we are investing in solutions that turn plastic waste into a valuable resource that can be used in the production of virgin-equivalent recycled material for reuse.

Ranjeet Bhatia, CEO

Our Solutions

Cyclyx

Cyclyx is a joint venture among Agilyx (50%), ExxonMobil (25%), and LyondellBasell (25%) to convert post-use plastic waste into high-quality feedstock for both mechanical and advanced recycling applications.

Styrenyx

We license our depolymerization technology for polystyrene waste recycling. We source, sell and supply all the necessary core equipment to make the project successful.

Agilyx Research Center

Through a collaborative approach, we offer design and engineering services, engineering integration, permitting support and other project support services that are tailored to our customers’ recycling needs.

Plastyx

Plastyx is a European-sourced feedstock supplier to the European advanced recycling industry. Through partnerships and material processing capabilities, the availability of high-quality polymers for food contact and other technical packaging applications is being rapidly scaled.

Investing in

solutions for plastic waste

Agilyx offers a compelling investment opportunity within the recycling industry, with well-funded projects driving growth and a clear pathway to profitability.

Moving towards a

lower-carbon future

Working with our customers, we are creating and supporting circular models where plastics can be used, recycled, and reused again and again. Closing the loop by replacing virgin plastic production with recycled material keeps plastics out of landfills and our environment, reduces demand for fossil resources, like oil and gas, and lowers greenhouse gas emissions.

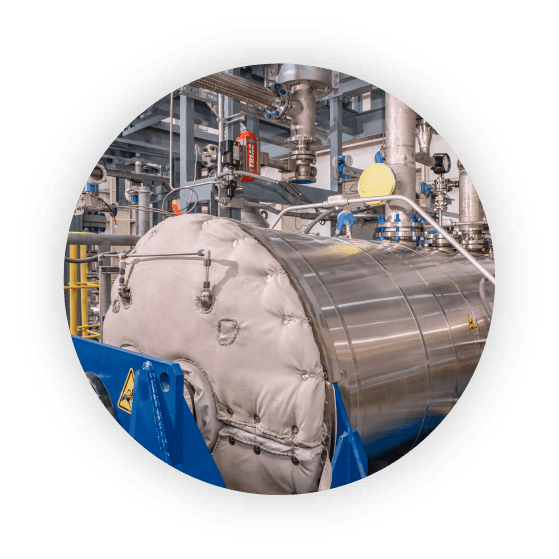

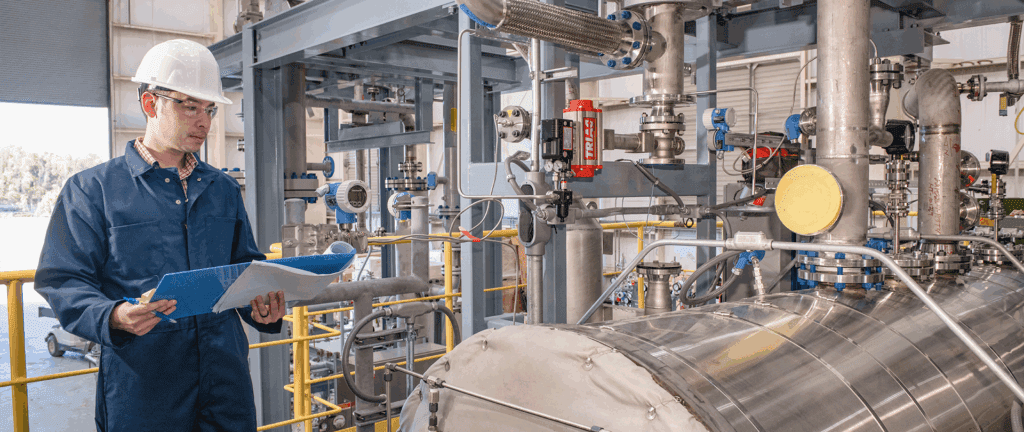

Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, is proud to announce that its depolymerization technology was successfully demonstrated during commissioning of Toyo Styrene’s 10 ton-per-day chemical recycling facility in Japan.

The recycling plant will convert post-use polystyrene into a styrene monomer enabled by Agilyx depolymerization technology. The styrene monomer will then be converted back into high value polystyrene products which bear a significantly lower carbon footprint than similar products made with virgin monomer.

Construction of the facility was completed in March 2024, at which time the commissioning process began. Last week, polystyrene was successfully depolymerized and converted to on-specification product during commissioning. The Toyo Styrene plant showcases the latest generation of Agilyx’s technology.

“The successful production of on-spec product during the commissioning process at Toyo’s facility is an exciting milestone,” stated Russ Main, interim CEO for Agilyx. “This achievement demonstrates the efficacy of Agilyx’s technology and brings us one step closer to project completion on the first polystyrene chemical recycling facility in Japan.”

Agilyx and Toyo will continue to partner and optimize the facility over the next few months.

For media inquiries:

communications@agilyx.com

For investor inquiries:

investors@agilyx.com

Agilyx ASA is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a chemical recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale waste polystyrene chemical recycling facility via pyrolysis enabling closed loop polystyrene plastic-to-plastic and holds 20 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at agilyx.com, subscribe to our newsletter or follow us on LinkedIn.

OSLO, Norway – February 29, 2024 – Agilyx ASA (OSE: AGLX; OTCQX: AGXXF) (“Agilyx” or “the company”), a technology company that enables customers to recycle the most challenging post-use plastics to high value, virgin-equivalent products, announced today that it has reached an agreement with Americas Styrenics (AmSty), its joint venture partner, to close Regenyx after successfully achieving the objectives defined in its five year formation agreement.

Regenyx, located in Tigard, Oregon (US), is a 50/50 joint venture between AmSty and Agilyx. The company converts post-use polystyrene back into its original components for production under AmSty’s PolyRenew® label. Regenyx showcases Agilyx depolymerization technology and enables AmSty to produce new polystyrene that is used to make products with the same quality and durability as virgin plastic. Over the course of the five-year project, Regenyx diverted over 6 million pounds of post-use polystyrene waste from landfills.

“Because of Regenyx, the new circular plastics economy now has a place for polystyrene, and this essential material that improves people’s lives has even more potential for growth,” said Tim Barnette, AmSty vice president of polymers and sustainability. “AmSty is proud to have been part of this long-term project that proves advanced recycling of polystyrene is not only feasible, it is the future.”

“We are very proud of our team and our company for the important work we’ve done over the past five years in Tigard,” said Russ Main, interim CEO of Agilyx. “Building this first-of-its-kind circular recycling model for polystyrene in the US opened the door for Agilyx to progress additional commercial projects, such as the Toyo Styrene plant in Japan which is nearing completion of commissioning and will showcase the latest generation of Agilyx technology.”

The Regenyx venture achieved many milestones including establishment of ISCC PLUS certification for the demonstrated circular pathway. The venture also allowed both parent companies to develop and progress additional projects and pathways at larger scale. Having successfully delivered its defined project objectives, Agilyx and AmSty will decommission the Regenyx venture at the end of the five-year agreement. The plant will cease operations by April 30, 2024, alongside the wind down of the venture.

For media inquiries:

Melanie Burger

Director, Corporate Communications

communications@agilyx.com

For investor inquiries:

Louise Bryant

SVP, Investor Relations & Sustainability

+44 7813 210 809

investors@agilyx.com

ABOUT AGILYX

Agilyx ASA is a technology company that enables customers to recycle difficult-to-recycle post-use plastics to high value, virgin-equivalent products. With a focus on diversion and conversion of plastic waste, Agilyx is uniquely positioned with a chemical recycling technology offering and an integrated feedstock solution by way of Cyclyx, an innovative feedstock management consortium of partners that drives up global plastic recycling rates by chemically fingerprinting plastic waste and matching it to appropriate recycling processes. Agilyx was the first to establish a commercial scale waste polystyrene chemical recycling facility via pyrolysis enabling closed loop polystyrene plastic-to-plastic and holds 20 patents. Agilyx conversion technology utilizes pyrolysis without a catalyst and can convert mixed waste plastic to naphtha and fuels or depolymerize specific plastics such as polystyrene and PMMA (acrylic) back into virgin-quality products. Learn more at www.agilyx.com or follow us on Linkedin.

INVESTOR REPORTS & PRESENTATIONS

The latest releases, reports and webcasts

Explore our latest presentation

2025

2025 H1 Results and Investor Presentation |

Report | Presentation | Webcast |

2025 Listing Prospectus |

Statement | ||

Styrenyx Product Carbon Footprint Report |

Report | ||

GreenDot Acquisition Management Presentation |

Presentation | ||

April Update Meeting |

Presentation | Webcast | |

2024

2024 Annual Report |

Report | ||

2024 H2 Results |

Report | ||

Investor Overview Presentation December |

Presentation | ||

Investor Overview Presentation November |

Presentation | ||

Green Finance |

Framework | S&P Second Party Opinion | |

2024 Listing Prospectus |

Statement | ||

2024 H1 Results and Investor Presentation |

Report | Presentation | Webcast |

2023

2023 Annual Report |

Report | ||

Cyclyx Investment |

Announcement | Presentation | Webcast |

2023 H1 Results and Investor Presentation |

Report | Presentation | Webcast |

2022

2022 Annual Report |

Report | ||

Prospectus for Uplisting on Oslo Børs |

Document | ||

2022 H1 Results and Investor Presentation |

Report | ||

2021

2021 Annual Report |

Report | Executive Summary | |

2021 H1 Results and Investor Presentation |

Report | ||

2020

2020 Annual Report |

Report | ||

Agilyx AS Financial Statements – first half 2020 |

Statements | ||

Join our team and help us change the way the world recycles

Discover opportunities

Our mission

Use innovative technology for good and help solve the problem of plastic waste

At Agilyx, we are investing in developing systems, processes, and technology to increase plastic waste recycling and promote a circular economy for plastic, reducing our dependency on fossil fuels and our carbon footprint. As we invest and build operations and strategic partnerships around the world, we are looking for people who are equally committed to helping change the way the world recycles.

We take care of the people who make our mission possible with a comprehensive benefits package

Up to 90% company-paid medical, dental and vision insurance premiums

Company-paid life insurance

Professional development and growth opportunities

401K with company matching employee contribution up to 3%

A flexible work environment for most roles

Competitive salary

Company-paid, long-term, and short-term disability

The ability to work remotely or hybrid in many roles

Many more company-provided benefits

Our Values

At Agilyx, we are committed to living our values.

We expect our employees to embrace and reflect these values in the work that they do every day as we move forward on our mission to use technology for good and help solve the problem of plastic waste.

Be safe

Safety first and always.

Be collaborative

Be inclusive and work together in delivering quality solutions.

Be Innovative

Use our entrepreneurial passion to drive continuous improvement in our mission to end plastic waste and protect our environment.

Be Responsible

Be accountable for doing the right thing in the right way, acting with integrity, and treating others with respect.