Why invest in Agilyx?

Building the first end-to-end, integrated solution for plastic waste

Agilyx is solving one of the greatest environmental challenges

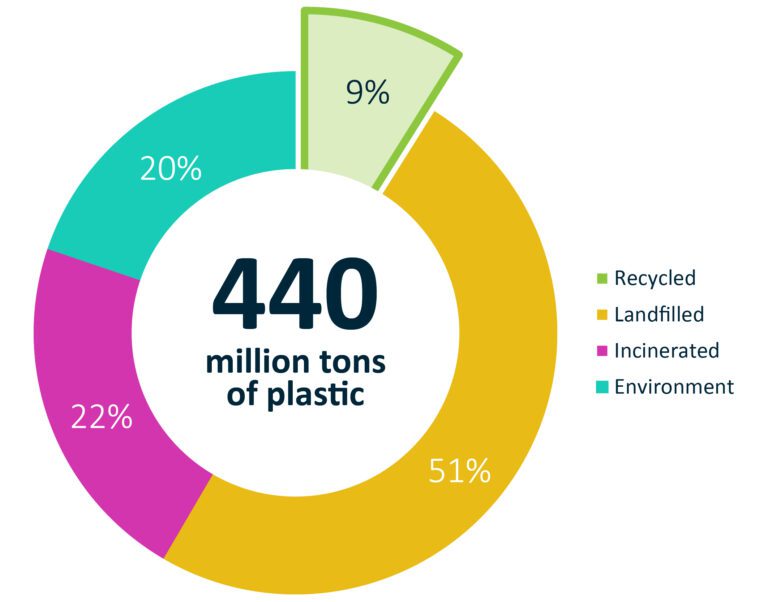

Plastic waste pollution is one of the greatest environmental challenges with 8 billion tons of plastic accumulated since 1950, and over 440 million tons produced every year. Only 9 percent of this plastic is recycled. Almost half of it is landfilled, 22 percent is incinerated and, worst of all, almost 20 percent is never collected at all, left to find its way into the environment.

Public regulations have been tightened, favoring recycling:

Global brand owners like Coca-Cola, Pepsico, Nestlé, Ikea, Walmart and Unilever have also made commitments to use

25-50% recycled materials in their products.

EU

50% recycling rate for plastic packaging by 2025 with EUR 800 tax per ton on non-recyclable plastic waste

UK

GBP 200 tax per ton on all plastic packaging with less than 30% recycled plastic

US

Recovery Act called for $500M in recycling infrastructure grants

Agilyx technology creates a tremendous market opportunity

Plastic can be hard to recycle, but Agilyx’s patented recycling technology turns even the most challenging plastics into circular resources.

Out of a total expected global demand for plastic of 500 million tons in 2030, between 20 and 105 million tons are expected to be delivered through recycled material.

This opportunity is equivalent to the output of approximately 1,900 Agilyx recycling plants by 2030 and up to 100 million tons of waste plastic processed into feedstock by Cyclyx per year.

Agilyx offers a unique end-to-end, integrated solution for plastic recycling

Recycling of plastic poses two equally important and equally demanding challenges:

- Waste to feedstock: Sourcing of the right amount of the right quality of waste plastic at the right time and at the lowest possible cost

- Feedstock to product: Efficient conversion of waste plastic to purified raw material

Agilyx is the only company that offers state of the art technology for both these processes and provides an end-to-end solution for plastic recycling.

The Agilyx technology is commercially validated with blue-chip partners

Agilyx has a long history with a technology that has been developed over 19 years with total investments of over USD 150 million.

The conversion technology is proven through a commercially operational plant in Oregon. Agilyx has gained an impressive roster of customers for its conversion technology, including AmSty, INEOS Styrolution, Technip Energies and Toyo Styrene.

The feedstock technology arm, Cyclyx, is a JV with ExxonMobil and LyondellBasell, and all the major plastic producers globally are among the consortium members.

The Agilyx strategy is asset-light, ready for scale up and rapid growth

Agilyx has an asset-light strategy with a primary focus on licensing of its technology. The pipeline of projects is growing rapidly and Agilyx is in the process of moving several projects into development and construction phases.

Cyclyx is making a step-change in terms of volume and number of consortium members, and significant feedstock volumes have started flowing through the company.

This means that revenue generation is accelerating and therefore helping to de-risk the Agilyx model.

Agilyx’s mid-term goal for 2025/26 is to generate annual revenue of USD 200-300 million. This revenue will be a function of reaching the goals of 165 tons per day of plant capacity in operation and 495-660 tons per day in development / construction. Cyclyx has a goal of processing feedstock volume of 650,000-900,000 tons per year in the medium term.